|

- 品牌:德国KAYSEN

- 发布日期: 2019-04-15

- 更新日期: 2026-01-06

| 品牌 | 德国KAYSEN |

| 连接形式 | 法兰 |

| 材质 | 不锈钢 |

| 型号 | KAYSEN |

| 工作压差 | 0 |

| 适用范围 | 水、污水、石油、化工、电子、饮料、食品 |

| 压力环境 | 常压 |

| 介质温度 | 1200℃ |

| 驱动方式 | 电动 |

| 适用介质 | 水 |

不锈钢离心泵(离心泵10大品牌)

KAYSEN凯森不锈钢离心泵概述

卧式单级单吸离心泵采用*进的水力模型,根据IS型单级单吸离心泵之性能参数和立式泵的独特结构组合设计,并严格按照国际iso2858进行设计制造,该产品轴封选用硬质合金机械密封装置,具有高效节能、性能可靠、安装使用方便等特点。

通过不锈钢离心泵与管路系统的特性曲线图分析了离心泵流量调节的几种主要方式:出口阀门调节、泵变速调节和泵的串、并联调节。用特性曲线图分析了出口阀门调节和泵变速调节两种方式的能耗损失,并进行了对比,指出离心泵用变速调节流量比用出口阀门调节流量可以更好的节约能耗,且节能效率与流量变化大小有关。在实际应用时应该注意变速调节的范围,才能更好的应用离心泵变速调节。

不锈钢离心泵是广泛应用于化工工业系统的一种通用流体机械。它具有性能适应范围广(包括流量、压头及对输送介质性质的适应性)、体积小、结构简单、操作容易、操作费用低等诸多优点。通常,所选离心泵的流量、压头可能会和管路中要求的不一致,或由于生产任务、工艺要求发生变化,此时都要求对泵进行流量调节,实质是改变离心泵的工作点。离心泵的工作点是由泵的特性曲线和管路系统特性曲线共同决定的,因此,改变任何一个的特性曲线都可以达到流量调节的目的。离心泵的流量调节方式主要有调节阀控制、变速控制以及泵的并、串联调节等。由于各种调节方式的原理不同,除有自己的优缺点外,造成的能量损耗也不一样,为了寻求*、能耗最小、最节能的流量调节方式,必须全面地了解离心泵的流量调节方式与能耗之间的关系。

主要特点:

不锈钢离心泵盖通过止口固定要中间支架上,然后通过泵体与中间支架止口的连接把泵盖夹紧在中间.泵体是轴向吸入,径向排出,脚支承式,可直接固定在底座上.悬架部件通过止口固定在中间支架上,并用悬架支架支撑在底座上.为拆卸方便,设计了加长联轴器,检修时可以不拆卸进出口联接管路、泵体和电动机。只需拆下长联轴器的中间联接件,即可退出转子部件进行检修。这是国际上一种通用的结构形式。 泵的密封型式采用填料密封或机械密封,由用户根据需要选用,同时根据需要允许采用适合于IS03069规定的密封空腔尺寸的其他结构的轴封型式(如带波纹管的机械密封和付叶轮密封等等)。

Germany Kaysen imported stainless steel centrifugal pump overview

The horizontal single-stage single-suction centrifugal pump adopts the most advanced hydraulic model. It is designed according to the performance parameters of the IS-type single-stage single-suction centrifugal pump and the unique structure of the vertical pump. It is designed and manufactured in strict accordance with the international iso2858. The hard alloy mechanical sealing device is adopted, which has the characteristics of high efficiency, energy saving, reliable performance, convenient installation and use.

Through the characteristic curve of the stainless steel centrifugal pump and the pipeline system, several main ways of adjusting the flow of the centrifugal pump are analyzed: the outlet valve adjustment, the pump shift regulation and the series and parallel adjustment of the pump. The characteristic curve is used to analyze the energy loss of the two methods of outlet valve regulation and pump speed regulation. The comparison shows that the variable speed regulation flow of the centrifugal pump can save energy and save energy by adjusting the flow rate with the outlet valve. It is related to the size of the flow change. In practical applications, attention should be paid to the range of shift regulation to better apply the centrifugal pump shift regulation.

Stainless steel centrifugal pumps are a general-purpose fluid machine widely used in chemical industrial systems. It has a wide range of performance (including flow, pressure head and adaptability to the nature of the transport medium), small size, simple structure, easy operation, low operating costs and many other advantages. Generally, the flow rate and pressure head of the selected centrifugal pump may be inconsistent with the requirements in the pipeline, or the production task and process requirements may change. At this time, the flow adjustment of the pump is required, which essentially changes the working point of the centrifugal pump. The working point of the centrifugal pump is determined by the characteristic curve of the pump and the characteristic curve of the piping system. Therefore, changing the characteristic curve of any one can achieve the purpose of flow regulation. The flow adjustment mode of the centrifugal pump mainly includes the regulating valve control, the variable speed control, and the parallel and series adjustment of the pump. Due to the different principles of various adjustment methods, in addition to their own advantages and disadvantages, the energy loss is not the same. In order to find the best, the lowest energy consumption, the most energy-saving flow regulation, it is necessary to fully understand the flow regulation of the centrifugal pump. The relationship between mode and energy consumption.

main feature:

The stainless steel centrifugal pump cover is fixed to the intermediate bracket through the stop, and then the pump cover is clamped in the middle by the connection between the pump body and the intermediate bracket. The pump body is axially sucked, radially discharged, and the foot is supported and can be directly fixed. On the base, the suspension component is fixed on the intermediate bracket through the stop, and is supported on the base by the suspension bracket. For the convenience of disassembly, the extension coupling is designed, and the inlet and outlet connection pipeline, the pump body and the electric motor. Simply remove the intermediate coupling of the long coupling and exit the rotor assembly for inspection. This is a common form of structure in the world. The seal type of the pump adopts packing seal or mechanical seal, which is selected by the user as needed, and other types of shaft seal type (such as mechanical seal with bellows and impeller seal) which are suitable for the sealed cavity size specified by IS03069 are allowed as required. and many more).

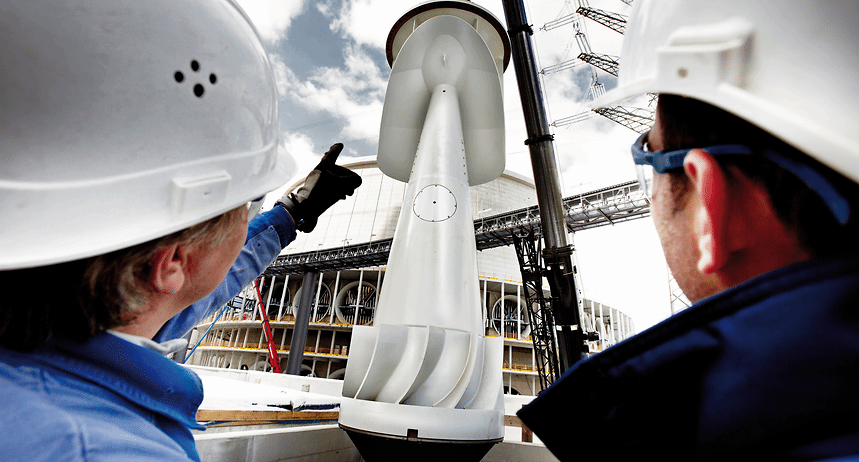

泵服务Pumps service

我们的服务团队提供从单一来源 - 安装,调试,维护,维修,咨询,升级,培训,备件和优化泵的所有工作。Our service team offers everything from a single source - Installation, commissioning, maintenance, repair, consulting, upgrades, training, spare parts and optimization of pumps.

一切从单一来源 我们长期的经验是您在现场调试,售后维护,维修,泵现代化和优化方面的优势。我们向您保证*的个人支持。 我们的服务团队为其他制造商的产品提供及时,专业和可靠的帮助。预订我们的服务套餐,您可以长期保证系统的*运行可靠性。我们会与您一起进行专家评估,从而创建透明度并根据您的需求制定*解决方案。在检查您的工厂后,我们确定其节约潜力并通过提高安装的泵的效率来实现它。另外,这个单独的解决方案降低了您的维护成本。您不必考虑人员,也不必考虑维护计划或实用程序。大会按照既定的时间表进行,并在我们训练有素的人员的协助下进行。

Everything from a single source Our long-standing experience is your advantage in commissioning on site, after-sales maintenance, repair, modernization and optimization of pumps. We guarantee you the best personal support. Our service team provides prompt, professional, and reliable assistance – also for other manufacturers’ products. Book our service package and you can be sure of the best operating reliability for your systems in the long term. We conduct an expert assessment together with you, thus creating transparency and making an optimum solution possible that is tailored to your needs. After examining your plant, we determine its savings potential and realize it by improving the efficiency of the pumps installed. Additionally, this individual solution lowers your maintenance costs. You do not have to think about personnel, nor about maintenance schedules or utilities. Assembly is conducted according to defined schedules and with assistance from our trained personnel.

我们的服务概述 · 供应原装备件 · 部署经过培训的人员 · 安装和启动 · 检查 · 维修,检修,维修 · 专家对早期故障检测进行机器评估 · 咨询和现代化 · 性能和振动测量 · 故障和损坏分析 · 可行性研究 · 泵和系统的能源咨询 · 制定维护计划 · 服务和维护协议 · 自动化和电力系统 · 电子设备 · 训练

An overview of our services · Supply of original spare parts · Deployment of trained personnel · Installation and start-up · Inspection · Repairs, overhauls, maintenance · Machine assessment by an expert for early fault detection · Consulting and modernization · Performance and vibration measurement · Fault and damage analyses · Feasibility studies · Energy consulting for pumps and systems · Preparation of maintenance schedules · Service and maintenance agreements · Automation and Electrical Power Systems · Electronic equipment · Training

不锈钢离心泵(离心泵10大品牌)