|

- 品牌:德国KAYSEN

- 发布日期: 2020-12-16

- 更新日期: 2025-12-28

| 外型尺寸 | |

| 品牌 | 德国KAYSEN |

| 货号 | |

| 用途 | 可用于抽粘度液体 |

| 型号 | KAYSEN |

| 工作压差 | 0 |

| 制造商 | |

| 压力环境 | 常压 |

| 介质温度 | 1200℃ |

| 驱动方式 | 电动 |

| 适用介质 | 水 |

| 是否进口 |

进口齿轮油泵(进口油泵品牌)

德国KAYSEN凯森进口齿轮油泵概述

本系列齿轮泵主要有齿轮、轴、泵体、安全阀、轴端密封所组成。齿轮油泵适用于输送不含固体颗粒和纤维,无腐蚀性,温度不高于80℃,粘度为5×10-6~1.5×10-3m2/s (5-00cSt)的润滑油或性质类似润滑油的其他液体。

主要特点:

1、齿轮油泵使用规定电压

线路电压不超过抽液泵铭牌上所规定电压的±10%方可使用。

2、齿轮油泵*装备

开箱后按结构示意图装配,接上电动机

(1)并紧接连电机

(2)使之泵体与电机为一体

(3)上接好出水轮管

3、齿轮油泵使用前检查各部件外型完好才能开机使用。

4、齿轮油泵不宜作空运转,使用时,抽吸完毕,即停泵,否则会加速叶轮密封件轴承等磨损。也可能磨损泵管,因本泵电机空载转速可达10000转/分。

5、齿轮油泵及时调换电刷,电刷磨损到将不能使用时,须及时调换(2只电刷同时调换)否则会使电刷与换向器接触不良引起坏损,损坏换向器,严重时会烧坏电枢。

6、齿轮油泵在下列情况下不得使用,在使用过程中如发现绝缘损坏,电源线工电缆护套破裂,插头插座开裂或接触不良,以及断续运转,出现严惩火花等故障时,电机外壳操作时,应立即进行修理。在未修复前不得使用。

7、齿轮油泵防止过载,使用时,凡遇转速异常或降低时,应即停机检查是否有杂物卡住叶轮或电机是否发生故障,抽液泵因故刹车时必须立即切断电源

8、齿轮油泵使用工具要爱惜,所有抽涂泵要小心轻放避免受到冲击。

Germany Kaysen imported gear oil pump overview

This series of gear pumps mainly consists of gears, shafts, pump bodies, safety valves and shaft end seals. Gear oil pump is suitable for conveying lubricating oil without solid particles and fibers, non-corrosive, temperature not higher than 80 ° C, viscosity of 5×10-6~1.5×10-3m2/s (5-00cSt) or similar lubrication Other liquids of oil.

main feature:

1, the gear oil pump uses the specified voltage

The line voltage shall not exceed ±10% of the voltage specified on the pumping pump nameplate.

2. How to equip the gear pump

After unpacking, assemble according to the structural diagram and connect the motor

(1) and immediately connected to the motor

(2) Make the pump body and the motor integrated

(3) Connect the water wheel tube

3. Before using the gear oil pump, check that the parts are in good condition before starting to use.

4. The gear oil pump should not be operated at idle. When using, the pumping is completed, that is, the pump is stopped, otherwise the bearing of the impeller seal will be accelerated. It is also possible to wear the pump tube because the pump motor has a no-load speed of 10,000 rpm.

5. The gear oil pump will change the brush in time. When the brush is worn and will not be used, it must be replaced in time (2 brushes are exchanged at the same time). Otherwise, the brush and the commutator may cause bad damage and damage the commutator. The armature will be burned out.

6. The gear oil pump should not be used under the following conditions. If the insulation damage is found during the use, the power cable sheath is broken, the plug and socket are cracked or the contact is bad, and the operation is intermittent, and the motor casing is operated when there is a serious punishment for sparks. Repairs should be made immediately. Do not use until unrepaired.

7. The gear oil pump prevents overload. When it is used, when the speed is abnormal or reduced, it should be stopped to check if there is any debris stuck in the impeller or the motor is faulty. If the pump is braked, the power must be cut off immediately.

8, gear oil pump use tools to be cherished, all pumping pumps should be handled with care to avoid impact.

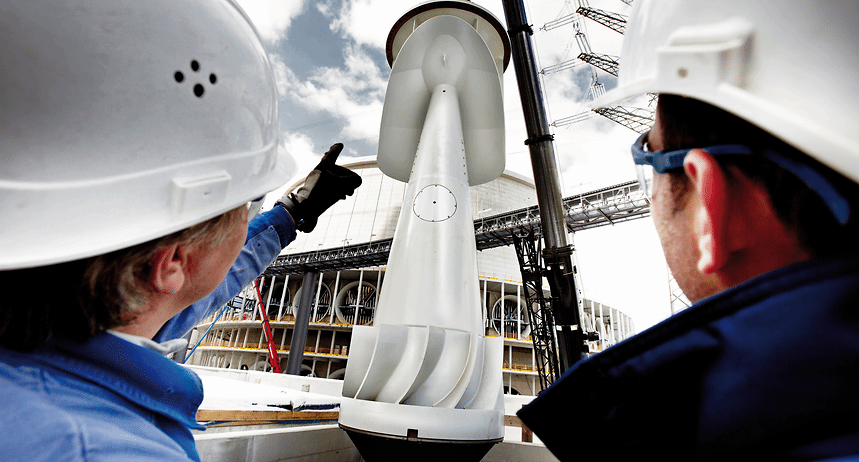

泵服务Pumps service

我们的服务团队提供从单一来源 - 安装,调试,维护,维修,咨询,升级,培训,备件和优化泵的所有工作。Our service team offers everything from a single source - Installation, commissioning, maintenance, repair, consulting, upgrades, training, spare parts and optimization of pumps.

一切从单一来源 我们长期的经验是您在现场调试,售后维护,维修,泵现代化和优化方面的优势。我们向您保证*的个人支持。 我们的服务团队为其他制造商的产品提供及时,专业和可靠的帮助。预订我们的服务套餐,您可以长期保证系统的*运行可靠性。我们会与您一起进行 评估,从而创建透明度并根据您的需求制定*解决方案。在检查您的工厂后,我们确定其节约潜力并通过提高安装的泵的效率来实现它。另外,这个单独的解决方案降低了您的维护成本。您不必考虑人员,也不必考虑维护计划或实用程序。大会按照既定的时间表进行,并在我们训练有素的人员的协助下进行。

Everything from a single source Our long-standing experience is your advantage in commissioning on site, after-sales maintenance, repair, modernization and optimization of pumps. We guarantee you the best personal support. Our service team provides prompt, professional, and reliable assistance – also for other manufacturers’ products. Book our service package and you can be sure of the best operating reliability for your systems in the long term. We conduct an expert assessment together with you, thus creating transparency and making an optimum solution possible that is tailored to your needs. After examining your plant, we determine its savings potential and realize it by improving the efficiency of the pumps installed. Additionally, this individual solution lowers your maintenance costs. You do not have to think about personnel, nor about maintenance schedules or utilities. Assembly is conducted according to defined schedules and with assistance from our trained personnel.

我们的服务概述 · 供应原装备件 · 部署经过培训的人员 · 安装和启动 · 检查 · 维修,检修,维修 · 对早期故障检测进行机器评估 · 咨询和现代化 · 性能和振动测量 · 故障和损坏分析 · 可行性研究 · 泵和系统的能源咨询 · 制定维护计划 · 服务和维护协议 · 自动化和电力系统 · 电子设备 · 训练

An overview of our services · Supply of original spare parts · Deployment of trained personnel · Installation and start-up · Inspection · Repairs, overhauls, maintenance · Machine assessment by an expert for early fault detection · Consulting and modernization · Performance and vibration measurement · Fault and damage analyses · Feasibility studies · Energy consulting for pumps and systems · Preparation of maintenance schedules · Service and maintenance agreements · Automation and Electrical Power Systems · Electronic equipment · Training

进口齿轮油泵(进口油泵品牌)