|

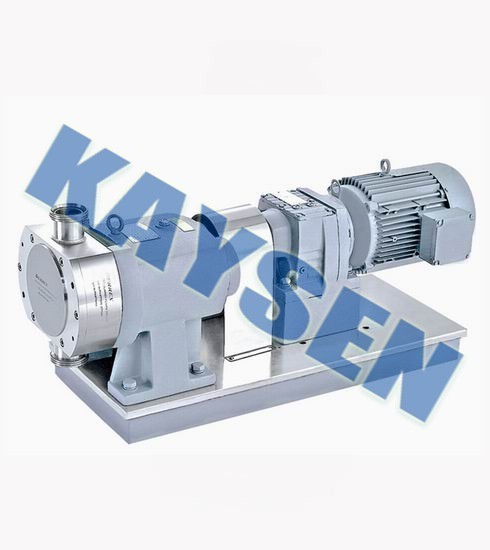

- 品牌:德国KAYSEN

- 货号:KS8369679

- 发布日期: 2019-10-12

- 更新日期: 2025-12-17

| 外型尺寸 | |

| 货号 | KS8369679 |

| 品牌 | KAYSEN |

| 用途 | 抽水、化工、制药、石油、冶金、染料、冶炼、电力、电镀、农药、造纸、食品、纺织等行业酸洗工艺、制酸制碱、喷漆工艺、有色金属冶炼中的电解液输送、离子膜项目中的氯水输送、废水处理、电镀、农药领域。 |

| 型号 | KAYSEN |

| 工作压差 | 0 |

| 压力环境 | 常压 |

| 介质温度 | 250℃ |

| 驱动方式 | 电动 |

| 适用介质 | 水 |

转子泵-不锈钢转子泵-KAYSEN泵业

GERMANY KAYSEN PUMP CO .,LTD

转子泵是指通过转子与泵体间的相对运动来改变工作容积,进而使液体的能量增加的泵。转子泵是一种旋转的容积式泵,具有正排量性质,其流量不随背压变化而变化。

主要特点:

●没有吸入阀和排出阀,它们的主要工作部件是泵壳和转子(如齿轮、螺杆、凸轮等)。

●与往复泵相比,转子作回转运动,没有冲击,转速较高,结构紧凑,体积较小。

●排出压力一般较高,但比往复泵要低,流量比往复泵还要小,效率较低,一般只适用于输送小量的液体,并大多作为辅助设备来使用。

●大多数转子泵是依靠本身输送的液体润滑的,故一般适用于输送具有润滑性和不含固体颗粒的液体。

●转子泵也是间歇排送液体的,所以流量的波动比离心泵大,比往复泵小,但可看成近似均匀。

●当转子表面上有液膜存在(输送润滑性液体)时,泵将具有自吸能力。

主要应用:

●石油石化行业:含油污水,轻质油,污油,重油,原油的输转,汽油、柴油扫仓,甲醇,乙醇卸车工位可以应用转子泵,替代液下泵以及隔膜泵等。

●市政行业:含固率5%以下剩余污泥,回流污泥输送,提升处理,离心机供料泵,自来水厂活性炭投加。

●粪便废水:农场高粘度粪便的输送,生活废水输送,餐厨垃圾输送。

●移动泵车:市政自来水排水,防洪排涝,农田灌溉。

高粘度转子泵故障解决方案:

凯森泵业高粘度转子泵在石化石油工业中完成高粘度液体(如合成橡胶,树脂,纤维的聚合液等)的输送,虽高粘度转子泵很耐用,但是工况现场总会出现一些故障,常见故障有三个,在此说明一下解决方案。

1、异常振动和噪声

因为高粘度转子泵工作介质的粘度较高,因而轻易发生吸空现象而激发较大的噪声。高粘度转子泵输送介质的粘度决定介质流动的难易程度,在输送过程中,流量和压力的变化,气泡的破裂都是噪音常见的原因,噪音也影响着高粘度转子泵的使用寿命。

对策:对于经常工作的压力较高的高粘度转子泵工作压力应比泵的额定压力低1-2个压力级。

2、无出口压力或压力缺乏

泵并不能发生压力,它只是输出流量。压力低或无压力,阐明高粘度转子泵没有吸入液体或走漏严重。

对策:电机输出功率偏小,高粘度转子泵排量选得过大或压力调得过高时,也会形成压力缺乏。当然,压力表损坏时也显现不出压力,此时可换装一个新的压力表搜检。

3、无流量或出液量缺乏

假如确认泵无流量输出,可能是因为泵装置有误,泵的转向有问题,或吸入侧(进液口及吸液管道)梗塞,出口止回阀装反或卡死了,也有可能是驱动轴断裂了。高粘度转子泵在转速过低时会引起液量缺乏,这种现象常常是因为泵的驱动安装打滑或功率缺乏所致。

对策:检查齿轮泵的实践转速,管路、泵与电机的联接及功率匹配状况等。

Rotor pump

Emulsifying pump

Positive displacement pump

A rotor pump is a pump that changes the working volume by the relative movement between the rotor and the pump body, thereby increasing the energy of the liquid. The rotor pump is a rotary positive displacement pump with positive displacement properties and its flow rate does not change with back pressure changes.

main feature:

? There are no suction and discharge valves, their main working components are the pump casing and rotor (such as gears, screws, cams, etc.).

● Compared with the reciprocating pump, the rotor performs rotary motion without impact, high speed, compact structure and small volume.

● The discharge pressure is generally higher, but lower than the reciprocating pump. The flow rate is smaller than the reciprocating pump and the efficiency is low. Generally, it is only suitable for conveying a small amount of liquid, and is mostly used as an auxiliary device.

● Most rotor pumps are lubricated by the liquid they are transported, so they are generally suitable for transporting liquids that are lubricious and free of solid particles.

●The rotor pump also intermittently discharges liquid, so the flow fluctuation is larger than the centrifugal pump and smaller than the reciprocating pump, but it can be regarded as approximately uniform.

● When there is a liquid film on the surface of the rotor (transporting lubricious liquid), the pump will have self-priming capability.

main application:

●Petroleum and petrochemical industry: oily sewage, light oil, dirty oil, heavy oil, crude oil transmission, gasoline, diesel sweeping, methanol, ethanol unloading station can use rotor pump, instead of submerged pump and diaphragm pump.

● Municipal industry: excess sludge with a solid content of 5% or less, return sludge transport, lifting treatment, centrifuge feed pump, and activated carbon for waterworks.

● Fecal waste water: the transportation of high-viscosity manure on the farm, the transportation of domestic wastewater, and the transportation of kitchen waste.

● Mobile pump truck: municipal tap water drainage, flood control and drainage, farmland irrigation.

High viscosity rotor pump failure solution:

Germany's Kaisen Pump Industry High-viscosity Rotor Pumps deliver high-viscosity liquids (such as synthetic rubber, resins, fiber polymerization fluids, etc.) in the petrochemical industry. Although high-viscosity rotor pumps are durable, there are always some on-site conditions. There are three faults and common faults. Explain the solution here.

1. Abnormal vibration and noise

Because of the high viscosity of the working medium of the high-viscosity rotor pump, the suction phenomenon easily occurs and a large noise is excited. The viscosity of the medium transported by the high-viscosity rotor pump determines the ease with which the medium flows. During the transport process, changes in flow and pressure, and cracking of the bubbles are common causes of noise, and noise also affects the service life of high-viscosity rotor pumps.

Countermeasure: The working pressure of the high viscosity rotor pump with high pressure for frequent work should be 1-2 pressure levels lower than the rated pressure of the pump.

2, no export pressure or lack of pressure

The pump does not produce pressure, it is just the output flow. Low or no pressure, clarifying that the high viscosity rotor pump does not inhale liquid or leaks severely.

Countermeasure: When the output power of the motor is too small, if the displacement of the high-viscosity rotor pump is too large or the pressure is too high, a lack of pressure will also occur. Of course, when the pressure gauge is damaged, there is no pressure. At this time, a new pressure gauge can be replaced for inspection.

3, no flow or lack of fluid

If it is confirmed that the pump has no flow output, it may be because the pump device is wrong, the pump has a problem in steering, or the inhalation side (inlet and suction pipe) is infarged, the outlet check valve is reversed or stuck, or it may be driven. The shaft broke. High-viscosity rotor pumps can cause a lack of fluid when the speed is too low. This is often caused by slippage or lack of power in the drive installation.

Countermeasures: Check the actual speed of the gear pump, the connection of the pipeline, the pump and the motor, and the power matching status.

位于Schw?bischGmünd的凯森Kaysen泵业有限公司是世界*的各种流体水泵和隔膜泵制造商之一。60多年来,凯森以“制造”的可靠性和质量达到了*标准。凭借我们全面的产品组合,我们支持世界各地的客户成功掌握供水,采矿,工业,化工,造纸,电力,食品,制药,污水和海上行业的苛刻抽水任务。作为上述领域创新技术的*供应商,我们是液体需要安全,高效和经济运输的*合作伙伴。

位于Schw?bischGmünd的凯森Kaysen泵业有限公司是世界*的各种流体水泵和隔膜泵制造商之一。60多年来,凯森以“制造”的可靠性和质量达到了*标准。凭借我们全面的产品组合,我们支持世界各地的客户成功掌握供水,采矿,工业,化工,造纸,电力,食品,制药,污水和海上行业的苛刻抽水任务。作为上述领域创新技术的*供应商,我们是液体需要安全,高效和经济运输的*合作伙伴。

凯森始终坚持“重质量,讲信誉”为宗旨。产品现畅销全国各地,并已逐步开发海外市场。公司多次被评为“重合同讲信用”企业,深得用户的信赖和广泛的赞誉。

The Kaysen Pumps GmbH in Schw?bischGmünd, Germany, is one of the world's leading manufacturers of fluid centrifugal pumps and diaphragm pumps. For more than 60 years, Kaisen has achieved the highest standards of reliability and quality of "Made in Germany". With our comprehensive product portfolio, we support customers around the world to successfully grasp the harsh pumping tasks of water supply, mining, industry, chemical, paper, electricity, food, pharmaceutical, sewage and marine industries. As a leading provider of innovative technology in these areas, we are the perfect partner for liquids to be safe, efficient and economical to transport. ,

Germany Kaysen always adhere to the "quality, stresses credibility" for the purpose. Products are selling all over the country, and has gradually developed overseas markets. The company has repeatedly been rated as "the contract with the letter" business, won the trust of users and extensive praise.