|

- 品牌:KAYSEN

- 货号:KS8369679

- 发布日期: 2019-10-12

- 更新日期: 2025-12-28

| 外型尺寸 | |

| 品牌 | KAYSEN |

| 货号 | KS8369679 |

| 用途 | 抽水、化工、制药、石油、冶金、染料、冶炼、电力、电镀、农药、造纸、食品、纺织等行业酸洗工艺、制酸制碱、喷漆工艺、有色金属冶炼中的电解液输送、离子膜项目中的氯水输送、废水处理、电镀、农药领域。 |

| 型号 | KAYSEN |

| 工作压差 | 0 |

| 制造商 | |

| 压力环境 | 常压 |

| 介质温度 | 250℃ |

| 驱动方式 | 电动 |

| 适用介质 | 其他 |

| 是否进口 |

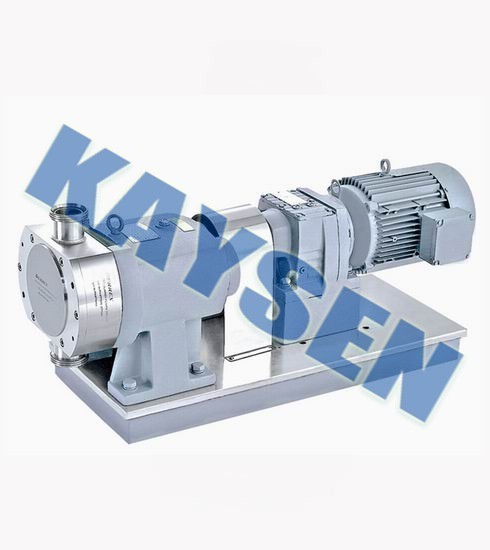

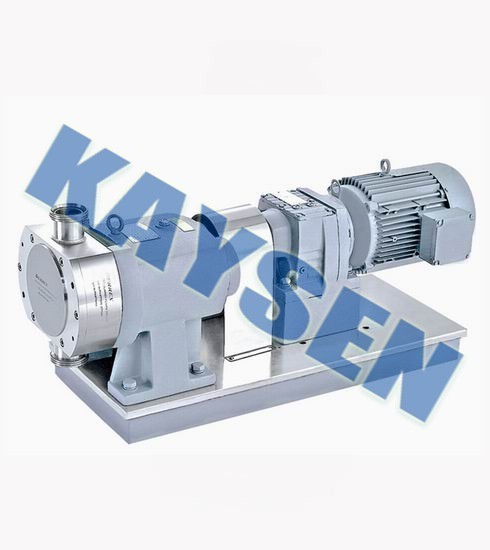

进口凸轮转子泵 德国KAYSEN转子泵

GERMANY KAYSEN PUMP CO .,LTD

凸轮转子泵属于回转式容积泵,效率高,寿命长,凸轮转子泵适用于输送含有固体颗粒的悬浮液体及具有腐蚀性和卫生性要求高的介质, 泵体内部与介质接触的零部件均采用不锈钢材料,并且可以根据介质不同的物理特性,改变泵的转速。

凸轮转子泵主要由凸轮转子、轴封、齿轮箱三部分组成,一对同步转动的传动齿轮带动凸轮转子转动,来实现对介质的输送。

凸轮转子泵轴封有机械密封和填料密封两种形式。可以根据不同工况条件进行选择和设计。

采用高强度铸铁的齿轮箱,螺旋齿轮及重负荷轴承,保证泵的使用性能及长的使用寿命。

主要部分为盒式装配,不用拆卸齿轮箱便能调整转子间隙。

凸轮转子泵由泵、电机和底座组成。

O型密封环材质主要为硅橡胶,当介质具有腐蚀性时,采用聚四氟乙烯材质,以保证泵的使用性能。

凸轮转子泵从电机端向泵看,为顺时针旋转。

由于凝固性粘稠度高的介质在尖锐的角落容易滞留附着,很难完全清除,因此3RP凸轮转子泵泵腔内的螺帽、沟槽均为半圆状,以便于清洗,防止介质长期存流而产生细菌。

可依据不同用途选择多种材质以满足用户使用。

主要特点:

●凸轮转子泵结构紧凑,体积小。

●凸轮转子泵通过同步齿轮驱动,转子之间没有摩擦,寿命长。

●凸轮转子泵可输送含有固体颗粒的介质。

●凸轮转子泵对介质的挤压和剪切很小,可忽略不计,脉动小。

●凸轮转子泵泵体腔拆卸、清洗方便。

●凸轮转子泵泵体腔内零部件多为圆形外形,尖角少,以便于清洗,防止介质长期存流而产生细菌。

●凸轮转子泵允许短时间的干转。

●凸轮转子泵输送方向:可逆,泵为完全对称的结构。

●凸轮转子泵标准法兰接口,接口也可以按客户要求提供。

主要应用:

凸轮转子泵广泛应用于食品、饮料、酿造、医药、日用化工、石油化工等行业。

高粘度泵如何选型:

凸轮转子泵被广泛应用于不同性质、不同粘度的介质输送,尤其在高粘度介质的运输方面,效果更加显著,也可作为高粘度泵使用。但是在它的选型中该注意哪些事项,才可以选择到合适自己工况的高粘度泵凯森泵业提醒您:在高粘度泵的选型中应综合考虑以下几方面因素:

一、必须考虑 高粘度泵的介质粘度,从而来确定高粘度泵的转速范围,根据高粘度泵的转速范围及所需工况条件下高粘度泵的正常流量范围,才能确定高粘度泵具体型号。

二、介质粘度的高低与高粘度泵的转速有着密不可分的关系。

三、真正了解介质在不同条件下的真正粘度。

四、高粘度泵在运转过程中常常会出现卡死、抱轴转不动的现象,主要原因是高粘度泵往往都是输送的高粘度的介质,有些是有一些杂质的混合物理。

Rotor pump

Emulsifying pump

Positive displacement pump

The cam rotor pump is a rotary positive displacement pump with high efficiency and long service life. The cam rotor pump is suitable for conveying suspended liquid containing solid particles and medium with high corrosiveness and hygienic requirements. The parts inside the pump body that are in contact with the medium are used. Stainless steel material, and can change the speed of the pump according to the different physical properties of the medium.

The cam rotor pump is mainly composed of a cam rotor, a shaft seal and a gear box. A pair of synchronously rotating transmission gears rotate the cam rotor to realize the conveying of the medium.

The cam rotor pump shaft seal has two forms: mechanical seal and packing seal. Can be selected and designed according to different working conditions.

High-strength cast iron gearboxes, helical gears and heavy-duty bearings ensure pump performance and long service life.

The main part is the box assembly, which can adjust the rotor clearance without disassembling the gear box.

The cam rotor pump consists of a pump, a motor and a base.

O-ring seal material is mainly silicone rubber. When the medium is corrosive, it is made of PTFE to ensure the performance of the pump.

The cam rotor pump looks clockwise from the motor end to the pump.

Because the medium with high cohesive viscosity is easy to stay in the sharp corners, it is difficult to completely remove it. Therefore, the nuts and grooves in the pump cavity of the 3RP cam rotor pump are semicircular, which is easy to clean and prevent long-term storage of the medium. And produce bacteria.

A variety of materials can be selected to suit the user's use.

main feature:

●The cam rotor pump is compact and small in size.

●The cam rotor pump is driven by the synchronous gear, there is no friction between the rotors, and the service life is long.

? The cam rotor pump delivers media containing solid particles.

●The squeezing and shearing of the medium by the cam rotor pump is small, negligible, and the pulsation is small.

●The cam rotor pump body cavity is easy to disassemble and clean.

●The parts of the cavity of the cam rotor pump are mostly round and have few sharp corners to facilitate cleaning and prevent bacteria from being generated by long-term storage of the medium.

● The cam rotor pump allows dry running for a short time.

● Cam rotor pump conveying direction: reversible, the pump is completely symmetrical structure.

●The standard flange interface of the cam rotor pump, the interface can also be provided according to customer requirements.

main application:

Cam rotor pumps are widely used in food, beverage, brewing, pharmaceutical, household chemicals, petrochemical and other industries.

How to choose a high viscosity pump:

The cam rotor pump is widely used for medium transportation of different properties and different viscosities, especially in the transportation of high viscosity media, and it can be used as a high viscosity pump. However, in the selection of the selection, you can choose the high-viscosity pump that suits your working conditions. Germany Kaisen Pumps reminds you that the following factors should be considered in the selection of high-viscosity pumps:

First, the viscosity of the high viscosity pump must be considered to determine the speed range of the high viscosity pump. According to the speed range of the high viscosity pump and the normal flow range of the high viscosity pump under the required working conditions, the specific model of the high viscosity pump can be determined. .

Second, the viscosity of the medium is inseparable from the speed of the high viscosity pump.

Third, really understand the true viscosity of the medium under different conditions.

Fourth, the high-viscosity pump often suffers from jamming and clasping during the operation. The main reason is that high-viscosity pumps are often transported with high-viscosity media, and some have a mixture of impurities.

位于Schw?bischGmünd的凯森Kaysen泵业有限公司是 *的各种流体水泵和隔膜泵制造商之一。60多年来,凯森以“制造”的可靠性和质量达到了*标准。凭借我们全面的产品组合,我们支持 各地的客户成功掌握供水,采矿,工业,化工,造纸,电力,食品,制药,污水和海上行业的苛刻抽水任务。作为上述领域创新技术的*供应商,我们是液体需要安全,高效和经济运输的*合作伙伴。

位于Schw?bischGmünd的凯森Kaysen泵业有限公司是 *的各种流体水泵和隔膜泵制造商之一。60多年来,凯森以“制造”的可靠性和质量达到了*标准。凭借我们全面的产品组合,我们支持 各地的客户成功掌握供水,采矿,工业,化工,造纸,电力,食品,制药,污水和海上行业的苛刻抽水任务。作为上述领域创新技术的*供应商,我们是液体需要安全,高效和经济运输的*合作伙伴。

凯森始终坚持“重质量,讲信誉”为宗旨。产品现 全国各地,并已逐步开发海外市场。公司多次被评为“重合同讲信用”企业,深得用户的信赖和广泛的赞誉。

The Kaysen Pumps GmbH in Schw?bischGmünd, Germany, is one of the world's leading manufacturers of fluid centrifugal pumps and diaphragm pumps. For more than 60 years, Kaisen has achieved the highest standards of reliability and quality of "Made in Germany". With our comprehensive product portfolio, we support customers around the world to successfully grasp the harsh pumping tasks of water supply, mining, industry, chemical, paper, electricity, food, pharmaceutical, sewage and marine industries. As a leading provider of innovative technology in these areas, we are the perfect partner for liquids to be safe, efficient and economical to transport. ,

Germany Kaysen always adhere to the "quality, stresses credibility" for the purpose. Products are selling all over the country, and has gradually developed overseas markets. The company has repeatedly been rated as "the contract with the letter" business, won the trust of users and extensive praise.

进口凸轮转子泵 德国KAYSEN转子泵