|

- 品牌:德国KAYSEN

- 货号:KS5819569

- 发布日期: 2019-10-11

- 更新日期: 2026-01-22

| 外型尺寸 | |

| 货号 | KS5819569 |

| 品牌 | KAYSEN |

| 用途 | 抽水、化工、制药、石油、冶金、染料、冶炼、电力、电镀、农药、造纸、食品、纺织等行业酸洗工艺、制酸制碱、喷漆工艺、有色金属冶炼中的电解液输送、离子膜项目中的氯水输送、废水处理、电镀、农药领域。 |

| 型号 | KAYSEN |

| 工作压差 | 0 |

| 压力环境 | 常压 |

| 介质温度 | 250℃ |

| 驱动方式 | 电动 |

| 适用介质 | 水 |

潜水推流器-推流器-KAYSEN泵业

GERMANY KAYSEN PUMP CO .,LTD

凯森低速潜水搅拌机又称潜水推流器,低速推流系列QJB型多功能潜水搅拌机适用于工业和城市污水处理厂曝气池和厌氧池、大型硝化及反硝化池、圆盘式活性污泥处理池、消毒车及工业搅拌。其产生低切向开放式的强力水流,可实现在大容积流体中产生水循环及硝化、脱氮和除磷阶段创建水流等。

主要特点:

●低速推流系列QJB型潜水推流器结构紧凑,体积小,重量轻,操作维护简单、安装检修方便、使用寿命长。

●叶轮具有很好的水力设计结构,工作效率高,后掠式叶片具有自洁功能可防杂物缠绕、堵塞。

●与曝气系统混合使用可使能耗大幅度降低,充氧量提高,有效防止沉淀。

●电机绕组绝缘等级为F级,防护等级为IP68,选用一次性润滑免维护轴承,具有油室泄露检测,使电机的工作更加安全可靠。

●两道独立的机械密封,机械密封的摩擦付材质为耐腐蚀的碳化钨。所有外露紧固件均为不锈钢材质。

●良好的电缆密封设计,排除了电缆漏水的隐患。

●标准部件采用点解分离技术,可以有效防止腐蚀。

主要应用:

●污水、废水、污泥水的混合、均匀

●稠化过程

●污泥脱水过程

●传热优化

●污水池清洁

●防止颗粒在池壁和池底的凝结和沉淀

●去除悬浮物

●防止结冰

●创建水流

●循环水等

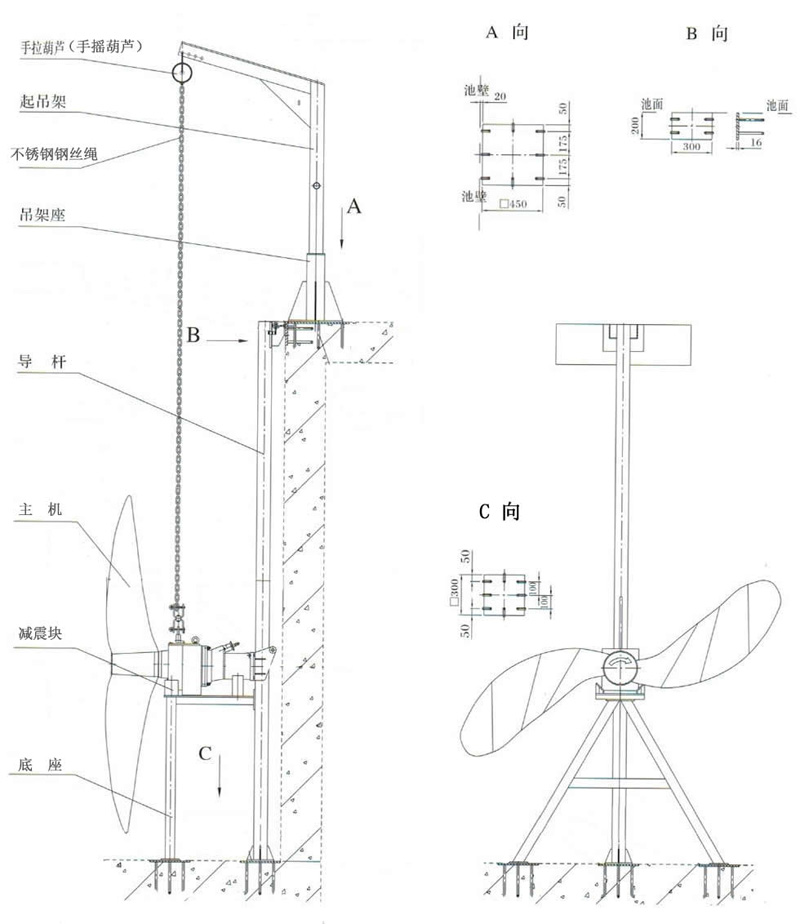

潜水推流器安装系统:

潜水推流器安装系统IV主要由手拉葫芦、起吊架、起吊环链、支座、导杆、中间支撑架(池深≤4m时无需配备)、限位架、底座等组成。导杆通过焊接在本体上的铰轴定位于支架、中间支撑架、底座同心轴线上,并可在水平面内转动±60°,以适应不同方向搅拌或推流,消除水池中的死区,使水流处于较好运行状态。潜水搅拌机通过导轮沿上下移动;起吊架可安装在支座上并可绕其定位轴线选择360°,以方便安装及维护。为增加潜水搅拌机运行时的可靠性,减缓潜水搅拌机运行中的振动,一般限位架直接焊接在导杆上,并在潜水搅拌机与限位架间加设减震块。限位架焊接在导杆上可在出厂前焊接,也可在现场安装时焊接。如用户无特殊要求,一般在出厂前焊接。

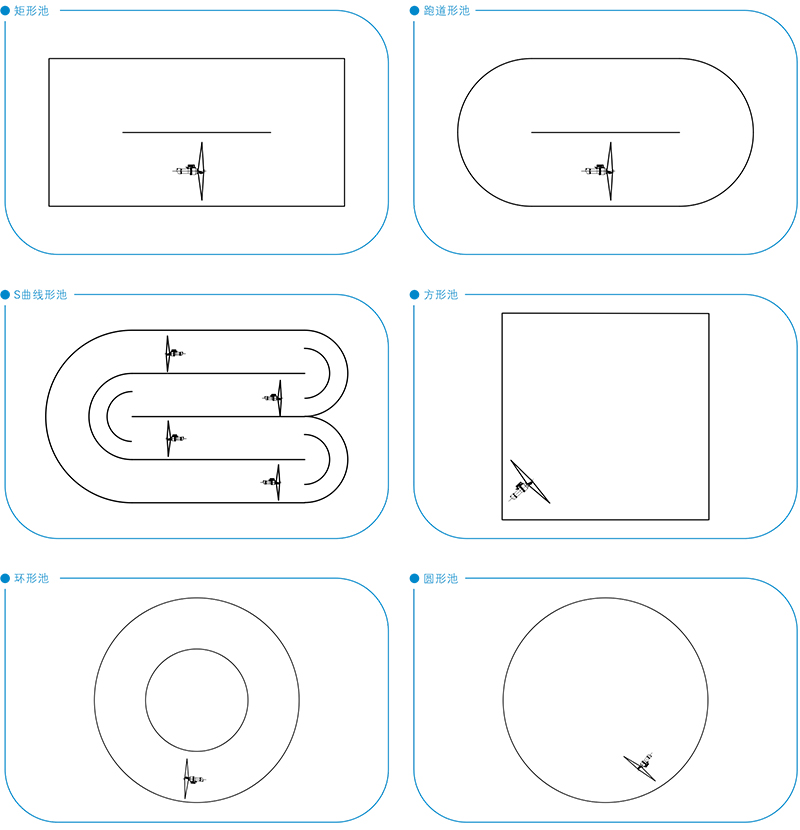

低速潜水推流器系列(注:如用于规则的池型,建议面对面错开布置)

潜水推流器注意事项极维护:

1. 定期将搅拌器吊起清理叶轮和泵体上的缠绕物,检查叶轮是否松动损坏,及时维修。

2. 搅拌器运行时观察液面的运行轨迹,如果非正常及时调整。

3. 观察搅拌器的固定杆的震动状况,震动过大需要吊起检查。

4. 搅拌器正常运行必须全部没过液面,运行时搅拌器上方应无涡流。

5. 液面低于搅拌器上方形成涡流时搅拌器不允许长时间运行。

6. 定期检查设备的密封状况,密封不良及时联系厂家检修。

QJB型多功能潜水搅拌机必须完全潜入水中工作,QJB型多功能潜水搅拌接受潜入深度≥90mm。不能在易燃易爆的环境下或有强腐蚀性液体的环境中工作。若用户有特殊使用要求,可与我公司技术工程部联系,我们为其提供比较合理的解决方案。

Germany Kaysen low-speed submersible mixer is also called submersible pusher. Low-speed push flow series QJB multi-function submersible mixer is suitable for industrial and urban sewage treatment plant aeration tank and anaerobic tank, large-scale nitrification and denitrification tank, disc type active Sludge treatment tank, disinfection vehicle and industrial mixing. It produces a low tangential open type of strong water flow, which can produce water circulation in large volume fluids and create water flow in the stages of nitrification, denitrification and phosphorus removal.

main feature:

●The low-speed push flow series QJB type submersible pusher is compact in structure, small in size, light in weight, simple in operation and maintenance, convenient in installation and maintenance, and long in service life.

●The impeller has a good hydraulic design structure and high working efficiency. The swept-back blade has a self-cleaning function to prevent entanglement and blockage of debris.

●In combination with the aeration system, energy consumption can be greatly reduced, oxygenation can be increased, and precipitation can be effectively prevented.

●The motor winding insulation grade is F grade, the protection grade is IP68, the imported one-time lubrication maintenance-free bearing is selected, and the oil chamber leakage detection is adopted to make the work of the motor more safe and reliable.

● Two independent mechanical seals, the friction of the mechanical seal is made of corrosion-resistant tungsten carbide. All exposed fasteners are made of stainless steel.

●Good cable sealing design eliminates the hidden danger of cable leakage.

●Standard parts use point-separation technology to prevent corrosion.

main application:

● Mixing and uniforming of sewage, wastewater and sludge water

● Thickening process

● Sludge dewatering process

● Heat transfer optimization

●Sewage pool cleaning

● Prevent condensation and precipitation of particles on the pool wall and bottom of the pool

●Removing suspended solids

● Prevent icing

●Create water flow

●Circulating water, etc.

Imported diving thruster installation system:

The submersible pusher installation system IV mainly consists of chain hoists, lifting jibs, hoisting rings, supports, guides, intermediate support frames (no need to be equipped when the depth is ≤ 4m), limit brackets, bases, etc. The guide rod is positioned on the bracket, the intermediate support frame and the concentric axis of the base by the hinge shaft welded on the body, and can be rotated by ±60° in the horizontal plane to adapt to the stirring or pushing flow in different directions, thereby eliminating the dead zone in the pool and making The water flow is in good working condition. The submersible mixer moves up and down through the guide wheel; the lifting bracket can be mounted on the support and can be 360° around its positioning axis for easy installation and maintenance. In order to increase the reliability of the operation of the submersible mixer and slow down the vibration during the operation of the submersible mixer, the general limit frame is directly welded on the guide rod, and a shock absorber block is added between the submersible mixer and the limit frame. The limit bracket is welded to the guide rod and can be welded before leaving the factory or welded during field installation. If the user has no special requirements, it is usually welded before leaving the factory.

Low-speed submersible pusher series (Note: If used for regular pool type, it is recommended to face-to-face staggered arrangement)

Diving thruster precautions Extreme maintenance:

1. Rinse the stirrer regularly to clean the windings on the impeller and the pump body, check whether the impeller is loose and damaged, and repair it in time.

2. Observe the running track of the liquid level when the agitator is running, if it is not adjusted properly.

3. Observe the vibration condition of the stirrer's fixed rod. If the vibration is too large, it needs to be lifted and checked.

4. The mixer must be operated without any liquid level. There should be no eddy current above the stirrer during operation.

5. The stirrer is not allowed to run for a long time when the liquid level is lower than the vortex above the stirrer.

6. Regularly check the sealing condition of the equipment. If the sealing is poor, contact the factory for repair.

The QJB multi-function submersible mixer must be fully submerged into the water. The QJB multi-purpose submersible agitation accepts a submerged depth of ≥90mm. Do not work in a flammable or explosive environment or in a highly corrosive liquid environment. If the user has special requirements, please contact our technical engineering department, we provide a more reasonable solution.

Cutting submersible sewage pump

Diving flow booster

Submersible mixed flow pump

Submersible return pump

Corrosion resistant sewage pump

位于Schw?bischGmünd的凯森Kaysen泵业有限公司是世界*的各种流体水泵和隔膜泵制造商之一。60多年来,凯森以“制造”的可靠性和质量达到了*标准。凭借我们全面的产品组合,我们支持世界各地的客户成功掌握供水,采矿,工业,化工,造纸,电力,食品,制药,污水和海上行业的苛刻抽水任务。作为上述领域创新技术的*供应商,我们是液体需要安全,高效和经济运输的*合作伙伴。

位于Schw?bischGmünd的凯森Kaysen泵业有限公司是世界*的各种流体水泵和隔膜泵制造商之一。60多年来,凯森以“制造”的可靠性和质量达到了*标准。凭借我们全面的产品组合,我们支持世界各地的客户成功掌握供水,采矿,工业,化工,造纸,电力,食品,制药,污水和海上行业的苛刻抽水任务。作为上述领域创新技术的*供应商,我们是液体需要安全,高效和经济运输的*合作伙伴。

凯森始终坚持“重质量,讲信誉”为宗旨。产品现畅销全国各地,并已逐步开发海外市场。公司多次被评为“重合同讲信用”企业,深得用户的信赖和广泛的赞誉。

The Kaysen Pumps GmbH in Schw?bischGmünd, Germany, is one of the world's leading manufacturers of fluid centrifugal pumps and diaphragm pumps. For more than 60 years, Kaisen has achieved the highest standards of reliability and quality of "Made in Germany". With our comprehensive product portfolio, we support customers around the world to successfully grasp the harsh pumping tasks of water supply, mining, industry, chemical, paper, electricity, food, pharmaceutical, sewage and marine industries. As a leading provider of innovative technology in these areas, we are the perfect partner for liquids to be safe, efficient and economical to transport. ,

Germany Kaysen always adhere to the "quality, stresses credibility" for the purpose. Products are selling all over the country, and has gradually developed overseas markets. The company has repeatedly been rated as "the contract with the letter" business, won the trust of users and extensive praise.