|

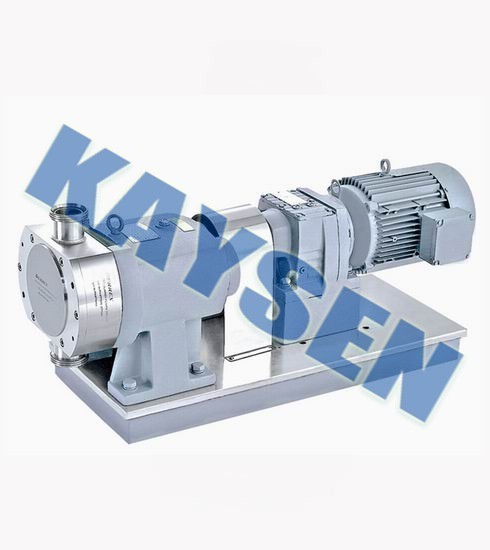

- 品牌:德国KAYSEN

- 货号:KS8369679

- 发布日期: 2019-10-12

- 更新日期: 2026-01-22

| 外型尺寸 | |

| 货号 | KS8369679 |

| 品牌 | KAYSEN |

| 用途 | 抽水、化工、制药、石油、冶金、染料、冶炼、电力、电镀、农药、造纸、食品、纺织等行业酸洗工艺、制酸制碱、喷漆工艺、有色金属冶炼中的电解液输送、离子膜项目中的氯水输送、废水处理、电镀、农药领域。 |

| 型号 | KAYSEN |

| 工作压差 | 0 |

| 压力环境 | 常压 |

| 介质温度 | 250℃ |

| 驱动方式 | 电动 |

| 适用介质 | 水 |

乳化泵-转子泵-KAYSEN泵业

GERMANY KAYSEN PUMP CO .,LTD

BRL3三级管线式分散乳化机,卫生级设计,在线CIP,零件表面均作精细抛光处理。工作腔内装有三组定、转子(细齿,中齿,粗齿),物料由轴向输入,经过三组定转子的高剪切分散、乳化、均质后由径向输出,对物料处理更精细。

主要特点:

●粒径分布范围窄,匀度高

●省时、高效、节约能耗

●噪音低,运转平稳

●消除批次间生产的品质差异

●无死角,物料 100% 通过分散剪切

●具有短距离、低扬程输送功能,可实现循环处理

●操作简单,维修方便

●可实现自动化控制

主要应用:

●混合:糖浆、香波、洗涤液、果汁浓缩液。酸奶、甜点、混合奶制品、油墨、瓷釉、

●分散混合:甲基纤维素溶液、胶质体溶液、碳化物溶液、油水乳化预混合、调味料生产、稳定剂溶液、烟尘、盐、氧化铝、农药。

●分散:悬浮液、药丸包衣、药物解聚、涂料分散、唇膏、蔬菜浓汤、芥末混合物、催化剂。消光剂、金属、颜料、改性沥青、纳米材料的制备和解聚。

●乳化:药乳液、药膏、雪花膏、面膜、面霜、乳化香精、油水乳化、树脂乳化、拉乳化、水性聚氨酯乳化、农药、

●均值:药乳液、药膏、雪花膏、面膜、面霜、组织均浆、奶制品、果汁、打印墨水、果酱

乳化泵常见故障及排除法:

故障 产生原因 排除方法 启动后无压力或调不上压力

1、先导阀的中、下节流孔堵塞; 2、卸载阀主阀卡住,或已损坏; 3、推力活塞处的密封圈损坏; 4、卸载阀先导阀卡住

| 故障 | 产生原因 | 排除方法 |

| 启动后无压力或调不上压力 | 1、先导阀的中、下节流孔堵塞; 2、卸载阀主阀卡住,或已损坏; 3、推力活塞处的密封圈损坏; 4、卸载阀先导阀卡住,或已损坏; | 1、疏通节流堵; 2、检查主阀是否卡住或损坏; 3、更换推力活塞处的密封圈; 4、检查先导阀是否卡住或损坏; |

| 压力脉动大,流量不足或无流量,甚至管道振动,噪声严重 | 1、泵吸液腔空气未排净; 2、柱塞密封圈处,吸液时进气; 3、吸液软管过细过长或有死弯; 4、吸排液阀弹簧断裂或阀芯损坏; 5、吸液阀螺堵未拧紧; 6、液箱的吸液过滤器被堵塞; | 1、拧松泵放气螺钉,放净重空气; 2、取出排液阀,往柱塞腔加满液; 3、调换吸液软管或消除死弯; 4、更换弹簧或更换阀芯; 5、拧紧吸液阀螺堵; 6、清洗液箱的吸液过滤器; |

| 柱塞密封处泄漏严重 | 1、柱塞密封圈磨损或损坏; 2、柱塞表面有严重划伤、拉毛; | 1、更换密封圈; 2、更换或修磨柱塞; |

| 泵运转时噪声大,有撞击声 | 1、轴瓦间隙加大; 2、泵内有杂物; 3、电机与泵的轴线不同轴; 4、柱塞与承压块间有间隙; | 1、更换轴瓦; 2、清楚杂物; 3、调整电机与泵,使其同轴; 4、拧紧压紧螺套; |

| 箱体温度过高 | 1、润滑油太脏或者不足; 2、轴瓦损坏或曲轴颈拉毛; | 1、加油或清洗油池,换油; 2、修理曲轴和调换轴瓦; |

| 泵压力突然升高超过卸载阀调定压力或安全阀调定压力 | 1、先导阀的上或下节流堵被堵塞; 2、先导阀的调压螺套被误调; 3、安全阀失灵; | 1、疏通节流堵; 2、重新调定压力; 3、检查调整或更换安全阀; |

| 支架停止供液时卸载阀动作频繁 | 1、支架系统漏液严重; 2、卸载阀单向阀漏液; 3、先导阀泄漏; | 1、消除工作面支架的漏液部位; 2、检查更换单向阀; 3、检查先导阀阀面及密封; |

| 乳化液温度高 | 1、先导阀的密封圈损坏; 2、单向阀处有溢流; | 1、检查先导阀的o形密封圈; 2、检查单向阀有无损坏; |

Rotor pump

Emulsifying pump

Positive displacement pump

BRL3 three-stage pipeline type dispersion emulsifier, sanitary design, online CIP, and fine polished surface of parts. There are three sets of stator and rotor (fine tooth, middle tooth, coarse tooth) in the working chamber. The material is input from the axial direction. After three sets of stator and rotor, the high shear dispersion, emulsification and homogenization are followed by radial output. fine.

main feature:

●The particle size distribution range is narrow and the formation is high

● Time saving, high efficiency and energy saving

●Low noise and smooth operation

● Eliminate the quality difference between batch production

● No dead angle, material 100% by dispersion shear

●With short distance and low lift conveying function, it can realize cycle processing

● Easy to operate and easy to maintain

●Automatic control

main application:

● Mixing: syrup, shampoo, washing liquid, juice concentrate. Yogurt, dessert, mixed dairy products, ink, enamel,

● Dispersion and mixing: methyl cellulose solution, colloidal solution, carbide solution, oil-water emulsion premixing, seasoning production, stabilizer solution, soot, salt, alumina, pesticide.

● Dispersion: suspension, pill coating, drug depolymerization, paint dispersion, lipstick, vegetable puree, mustard mixture, catalyst. Preparation and depolymerization of matting agents, metals, pigments, modified asphalts, nanomaterials.

●Emulsification: drug lotion, ointment, cream, mask, face cream, emulsified essence, oil-water emulsification, resin emulsification, emulsification, water-based polyurethane emulsification, pesticide,

● Mean: drug lotion, ointment, cream, mask, face cream, tissue homogenate, dairy products, juice, printing ink, jam

Emergent pump common faults and elimination methods:

Fault Cause Remedy No pressure or pressure after starting

1. The middle and lower orifices of the pilot valve are blocked; 2. The main valve of the unloading valve is stuck or damaged; 3. The sealing ring at the thrust piston is damaged; 4. The unloading valve pilot valve is stuck.

Fault Cause Remedy

No pressure or adjustment after starting. 1. The middle and lower orifices of the pilot valve are blocked.

2. The main valve of the unloading valve is stuck or damaged.

3. The seal ring at the thrust piston is damaged;

4. The unloading valve pilot valve is stuck or damaged; 1. The throttle block is blocked;

2. Check if the main valve is stuck or damaged;

3. Replace the seal ring at the thrust piston;

4. Check if the pilot valve is stuck or damaged;

The pressure pulsation is large, the flow is insufficient or no flow, and even the pipeline vibrates, the noise is serious. 1. The air in the pump suction chamber is not drained;

2. At the plunger seal ring, the air intake when aspirating;

3. The liquid suction hose is too long or too long;

4. The spring of the suction and discharge valve is broken or the spool is damaged;

5. The suction valve screw plug is not tightened;

6. The liquid suction filter of the liquid tank is blocked; 1. Loosen the pump bleed screw and release the heavy air;

2. Take out the drain valve and fill the plunger chamber with liquid;

3. Change the suction hose or eliminate the dead bend;

4. Replace the spring or replace the valve core;

5. Tighten the suction valve screw plug;

6. The liquid suction filter of the cleaning liquid tank;

Leakage at the plunger seal is severe. 1. The plunger seal is worn or damaged.

2. The surface of the plunger is severely scratched and pulled; 1. Replace the sealing ring;

2. Replace or repair the plunger;

When the pump is running, the noise is large, and there is a crashing sound. 1. The bearing bush clearance is increased;

2. There are debris in the pump;

3. The axis of the motor and the pump are different axes;

4. There is a gap between the plunger and the pressure block; 1. Replace the bearing bush;

2, clear debris;

3. Adjust the motor and pump to make it coaxial;

4. Tighten the compression nut;

The temperature of the cabinet is too high 1. The lubricating oil is too dirty or insufficient;

2. Damage to the bearing bush or cranking of the crankshaft; 1. Refuel or clean the oil pool and change the oil;

2. Repair the crankshaft and change the bearing bush;

The pump pressure suddenly rises above the unloading valve setting pressure or the relief valve setting pressure. 1. The upper or lower throttle plug of the pilot valve is blocked;

2. The pressure regulating screw sleeve of the pilot valve is mis-adjusted;

3, the safety valve fails; 1, dredge throttle block;

2. Reset the pressure;

3. Check and adjust or replace the safety valve;

When the bracket stops feeding, the unloading valve moves frequently. 1. The bracket system leaks seriously;

2. The unloading valve check valve leaks;

3. Leakage of the pilot valve; 1. Eliminate the leaking part of the working face bracket;

2. Check and replace the check valve;

3. Check the valve surface and seal of the pilot valve;

The temperature of the emulsion is high. 1. The sealing ring of the pilot valve is damaged.

2. There is overflow at the check valve; 1. Check the o-ring seal of the pilot valve;

2. Check the check valve for damage;

位于Schw?bischGmünd的凯森Kaysen泵业有限公司是世界*的各种流体水泵和隔膜泵制造商之一。60多年来,凯森以“制造”的可靠性和质量达到了*标准。凭借我们全面的产品组合,我们支持世界各地的客户成功掌握供水,采矿,工业,化工,造纸,电力,食品,制药,污水和海上行业的苛刻抽水任务。作为上述领域创新技术的*供应商,我们是液体需要安全,高效和经济运输的*合作伙伴。

位于Schw?bischGmünd的凯森Kaysen泵业有限公司是世界*的各种流体水泵和隔膜泵制造商之一。60多年来,凯森以“制造”的可靠性和质量达到了*标准。凭借我们全面的产品组合,我们支持世界各地的客户成功掌握供水,采矿,工业,化工,造纸,电力,食品,制药,污水和海上行业的苛刻抽水任务。作为上述领域创新技术的*供应商,我们是液体需要安全,高效和经济运输的*合作伙伴。

凯森始终坚持“重质量,讲信誉”为宗旨。产品现畅销全国各地,并已逐步开发海外市场。公司多次被评为“重合同讲信用”企业,深得用户的信赖和广泛的赞誉。

The Kaysen Pumps GmbH in Schw?bischGmünd, Germany, is one of the world's leading manufacturers of fluid centrifugal pumps and diaphragm pumps. For more than 60 years, Kaisen has achieved the highest standards of reliability and quality of "Made in Germany". With our comprehensive product portfolio, we support customers around the world to successfully grasp the harsh pumping tasks of water supply, mining, industry, chemical, paper, electricity, food, pharmaceutical, sewage and marine industries. As a leading provider of innovative technology in these areas, we are the perfect partner for liquids to be safe, efficient and economical to transport. ,

Germany Kaysen always adhere to the "quality, stresses credibility" for the purpose. Products are selling all over the country, and has gradually developed overseas markets. The company has repeatedly been rated as "the contract with the letter" business, won the trust of users and extensive praise.