|

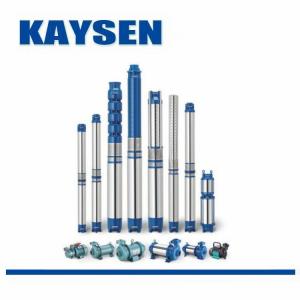

- 品牌:KAYSEN

- 货号:KS5889569

- 发布日期: 2019-10-11

- 更新日期: 2025-12-17

| 外型尺寸 | |

| 品牌 | KAYSEN |

| 货号 | KS5889569 |

| 用途 | 抽水、化工、制药、石油、冶金、染料、冶炼、电力、电镀、农药、造纸、食品、纺织等行业酸洗工艺、制酸制碱、喷漆工艺、有色金属冶炼中的电解液输送、离子膜项目中的氯水输送、废水处理、电镀、农药领域。 |

| 型号 | KAYSEN |

| 工作压差 | 0 |

| 制造商 | |

| 压力环境 | 常压 |

| 介质温度 | 250℃ |

| 驱动方式 | 电动 |

| 适用介质 | 水 |

| 是否进口 |

进口井用潜水泵-深井泵-德国KAYSEN泵业

GERMANY KAYSEN PUMP CO .,LTD

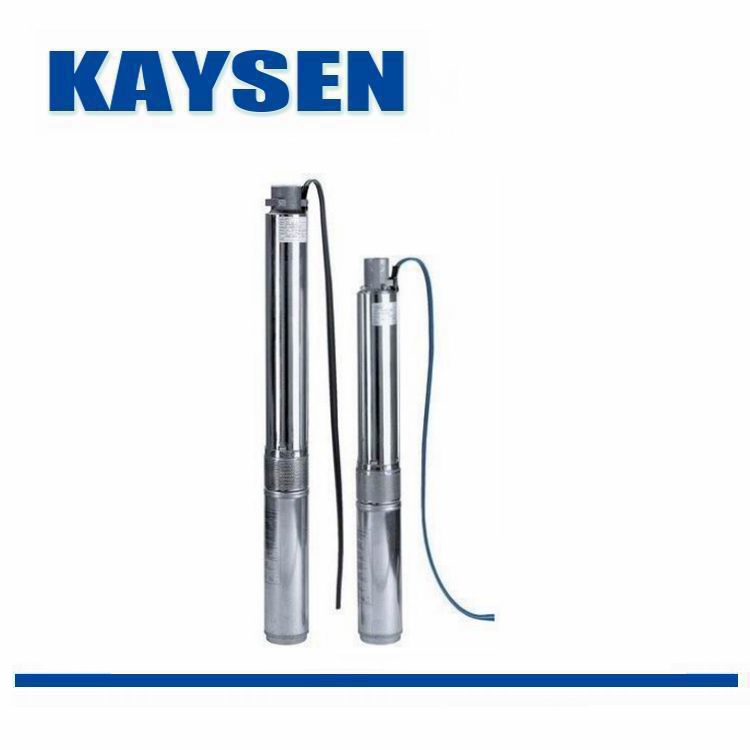

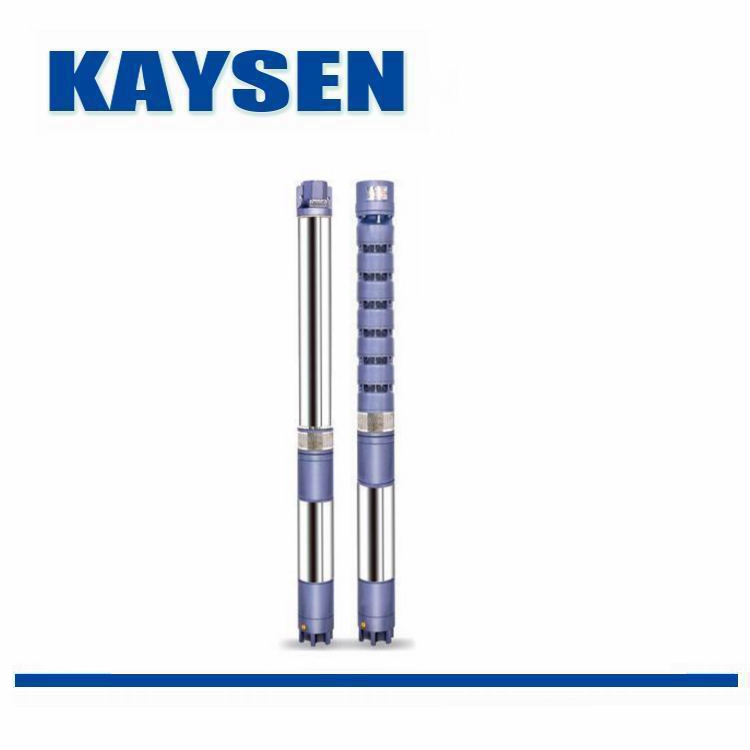

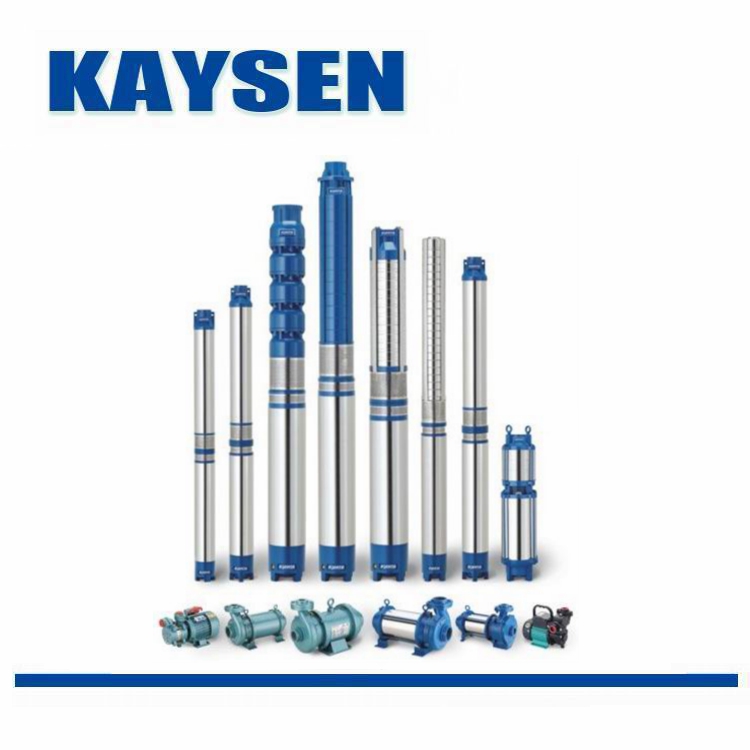

德国凯森进口井用潜水泵是深井提水的重要设备.使用时整个机组潜入水中工作.把地下水提取到地表,是生活用水.矿山抢险.工业冷却.农田灌溉.海水提升.轮船调载.还可用于喷泉景观.热水潜水泵用于温泉洗浴.居民小区利用地热采暖时可作为地热循环泵等,用途十分广泛. 该产品是地热开发利用工程的重要提水设备,耐热、防腐、抗老化,使用温度120℃,通过国家部级鉴定。潜水电机外壳采用不锈钢及锡青铜材料。

主要特点:

●单级扬程高.单级泵壳高度矮.缩短了整机的高度增加了运行的稳定性。

●泵轴直径远大于国标直径.为提取超级深井的地下水源增加了安全系数。

●铸件采用HT200(普通铸件在HT150以下)超级深井泵壳采用球墨铸铁.铸钢.不锈钢来提高泵壳的承压系数。

●逆止阀采用独特的设计方式.从根本上避免了超深井潜水泵.因停泵时回水水锤冲击力过大而造成的阀体断裂机组掉井的弊端。

●轴向力小增加了电机的使用寿命。

主要优点:

●具有结构紧凑

●体积小

●安装、使用维护方便

●运输安全可靠

●节约能源等优点

主要应用:

●消防用抽水设备

●供水干管

●农业灌溉、矿场

●地热水井

●石化行业、具有腐蚀性和研磨性液体的化学系统

●钢厂的热处理设施

井用潜水泵的维护和注意事项:

为了保证井用潜水泵装置的正常工作,减小故障率,延长使用寿命,平时必须加强对深井潜水泵的维修维护,定期对潜水泵及其控制系统进行全面的维护保养,每年至少做一次全面的预防性检修。

井用潜水泵使用中需要注意的维护与保养方法如下:

1、深井泵装置的使用环境应经常保持干燥。立式电动机表面应保持清洁,进风口不应受尘土、纤维等杂物的阻碍,保证风道畅通无阻。电动机周围不应放置热源,也尽量不要在户外直射阳光下使用,以免运行中过热造成损坏。

2、深井泵装置运行时,应经常注意有关仪表的读数,并定时记录水泵运行中的有关参数(如电动机的电压、

3、运行中如发现有任何不正常的响声,应立即停车进行检查。如发现电动机的防逆转装置失去作用时,必须进行检修,清楚污物,使其能良好地工作。

4、电动机控制装置的过电流保护或短路保护连续发生动作时,应检查故障是来自电动机过载还是保护装置定制太低。如果是保护装置的整定值太低,应调整保护装置的整定值至合理的数值;如果是因电动机过载造成,应及时检查电动机过载的原因,消除过载故障才可重新投入运行。

5、每次运行中因故停车时,应注意检查电动机油标的油位,如发现油位低于油标的一半时,应及时补充新油,以保证电动机角接触球轴承的可靠润滑。

Kaysen well submersible pump is an important equipment for deep well water pumping. When using, the whole unit is submerged into the water. The groundwater is extracted to the surface, which is domestic water. Mine rescue. Industrial cooling. Farmland irrigation. Seawater lifting. Ship loading. Can also be used Fountain landscape. Hot water submersible pump is used for hot spring bath. Residential area can be used as geothermal circulation pump when using geothermal heating. It is widely used. It is an important water-lifting equipment for geothermal development and utilization project, heat-resistant, anti-corrosion and anti-aging. The temperature is 120 ° C and passed the national level appraisal. The submersible motor housing is made of stainless steel and tin bronze.

main feature:

● Single stage lift height. Single stage pump casing height is short. Shortening the height of the whole machine increases the stability of operation.

● The diameter of the pump shaft is much larger than the diameter of the national standard. It increases the safety factor for extracting the groundwater source of the super deep well.

●The castings are made of HT200 (common castings below HT150). Super deep well pump casings are made of ductile iron, cast steel and stainless steel to increase the pressure coefficient of the pump casing.

●The check valve adopts a unique design method. It fundamentally avoids the disadvantages of the ultra-deep well submersible pump. The valve body breakage unit is lost due to the excessive impact force of the return water hammer when the pump is stopped.

● The small axial force increases the service life of the motor.

The main advantage:

● has a compact structure

● small size

● Easy to install, use and maintain

● Transportation is safe and reliable

●Energy saving and other advantages

main application:

●Fire pumping equipment

●Water supply main pipe

●Agricultural irrigation, mines

●Geothermal well

● petrochemical industry, chemical systems with corrosive and abrasive liquids

● Heat treatment facilities of steel mills

Maintenance and precautions for well submersible pumps:

In order to ensure the normal operation of the submersible pump unit for wells, reduce the failure rate and prolong the service life, it is necessary to strengthen the maintenance and repair of the deep well submersible pump, and regularly carry out comprehensive maintenance on the submersible pump and its control system, at least once a year. Preventive maintenance.

The maintenance and maintenance methods that need to be paid attention to when using the submersible pump are as follows:

1. The environment in which the deep well pump unit is used should be kept dry. The surface of the vertical motor should be kept clean, and the air inlet should not be obstructed by dust, fibers and other debris, ensuring unimpeded air passage. Heat sources should not be placed around the motor, and should not be used outdoors under direct sunlight to avoid damage caused by overheating during operation.

2. When the deep well pump device is running, always pay attention to the readings of the relevant instruments, and regularly record the relevant parameters (such as the voltage of the motor,

3. If any abnormal sound is found during operation, stop immediately for inspection. If the anti-reverse device of the motor is found to be ineffective, it must be repaired to clear the dirt so that it can work well.

4. When the overcurrent protection or short circuit protection of the motor control device continuously occurs, it should be checked whether the fault is from the motor overload or the protection device is too low. If the setting value of the protection device is too low, the setting value of the protection device should be adjusted to a reasonable value; if it is caused by the overload of the motor, the cause of the motor overload should be checked in time, and the overload fault can be eliminated before it can be put back into operation.

5. When parking for any reason, please pay attention to check the oil level of the motor oil standard. If the oil level is lower than half of the oil standard, the new oil should be replenished in time to ensure the reliable lubrication of the angular contact ball bearing of the motor.

Stainless steel hot spring pump

Long shaft deep well pump

Stainless steel deep well pump

Submersible electric pump

位于Schw?bischGmünd的凯森Kaysen泵业有限公司是 *的各种流体水泵和隔膜泵制造商之一。60多年来,凯森以“制造”的可靠性和质量达到了*标准。凭借我们全面的产品组合,我们支持 各地的客户成功掌握供水,采矿,工业,化工,造纸,电力,食品,制药,污水和海上行业的苛刻抽水任务。作为上述领域创新技术的*供应商,我们是液体需要安全,高效和经济运输的*合作伙伴。

位于Schw?bischGmünd的凯森Kaysen泵业有限公司是 *的各种流体水泵和隔膜泵制造商之一。60多年来,凯森以“制造”的可靠性和质量达到了*标准。凭借我们全面的产品组合,我们支持 各地的客户成功掌握供水,采矿,工业,化工,造纸,电力,食品,制药,污水和海上行业的苛刻抽水任务。作为上述领域创新技术的*供应商,我们是液体需要安全,高效和经济运输的*合作伙伴。

凯森始终坚持“重质量,讲信誉”为宗旨。产品现 全国各地,并已逐步开发海外市场。公司多次被评为“重合同讲信用”企业,深得用户的信赖和广泛的赞誉。

The Kaysen Pumps GmbH in Schw?bischGmünd, Germany, is one of the world's leading manufacturers of fluid centrifugal pumps and diaphragm pumps. For more than 60 years, Kaisen has achieved the highest standards of reliability and quality of "Made in Germany". With our comprehensive product portfolio, we support customers around the world to successfully grasp the harsh pumping tasks of water supply, mining, industry, chemical, paper, electricity, food, pharmaceutical, sewage and marine industries. As a leading provider of innovative technology in these areas, we are the perfect partner for liquids to be safe, efficient and economical to transport. ,

Germany Kaysen always adhere to the "quality, stresses credibility" for the purpose. Products are selling all over the country, and has gradually developed overseas markets. The company has repeatedly been rated as "the contract with the letter" business, won the trust of users and extensive praise.