|

- 品牌:德国KAYSEN

- 货号:KS5889569

- 发布日期: 2019-10-11

- 更新日期: 2026-01-22

| 外型尺寸 | |

| 货号 | KS5889569 |

| 品牌 | KAYSEN |

| 用途 | 抽水、化工、制药、石油、冶金、染料、冶炼、电力、电镀、农药、造纸、食品、纺织等行业酸洗工艺、制酸制碱、喷漆工艺、有色金属冶炼中的电解液输送、离子膜项目中的氯水输送、废水处理、电镀、农药领域。 |

| 型号 | KAYSEN |

| 工作压差 | 0 |

| 压力环境 | 常压 |

| 介质温度 | 250℃ |

| 驱动方式 | 电动 |

| 适用介质 | 水 |

长轴深井泵-深井泵-KAYSEN泵业

GERMANY KAYSEN PUMP CO .,LTD

长轴深井泵多数是一个立式单吸多级离心泵,其叶轮装在井中动水位以下,动力机设置在井上,通过传动长轴驱动叶轮在导流壳内旋转,水流沿导流壳与叶轮之间的流道,经输水管向上提升到地面。该泵使用寿命和检修期较长,使用范围广泛,而且能够在较恶劣的环境中使用,检修也极为方便。

主要特点:

●采用护管可靠地保护了传动部件和润滑部件

采用护管结构,使输送介质在护管外流动,不与传动部件和润滑部件接触,不因泵输送介质中含有泥砂、氧化铁皮、油污等异物,而影响泵的传动部件和润滑部件工作。

●特殊的润滑方式和轴承结构保证了泵长期稳定运行

泵的轴承除采用常规的橡胶导轴承外,还根据特殊需要,采用了石墨轴承、硬质合金轴承,提高泵的耐磨耐温的使用性能。

泵的润滑方式根据使用环境条件不同,可选用2~3kg/cm2的自来水(清洁水)润滑泵下轴承。在无自来水(清洁水)的特殊环境中,泵采用了自润滑方式:一种是使用钙基润滑脂润滑,此润滑方式完全采用了国外先进技术,泵无论在哪种特殊环境中,均可正常长期使用。另一种润滑方式是泵输送介质较清洁时,采用泵体内输送介质进行自润滑。

●使用高强度材质,泵具有良好的稳定性

泵的叶轮和轴采用了耐磨高强度不锈钢材质,扬水管及护管采用了无缝钢管或不锈钢管,强度高,稳定性好。

●泵能在特殊的恶劣环境中长期正常运行

●泵结构紧凑,安装调试及维护方便

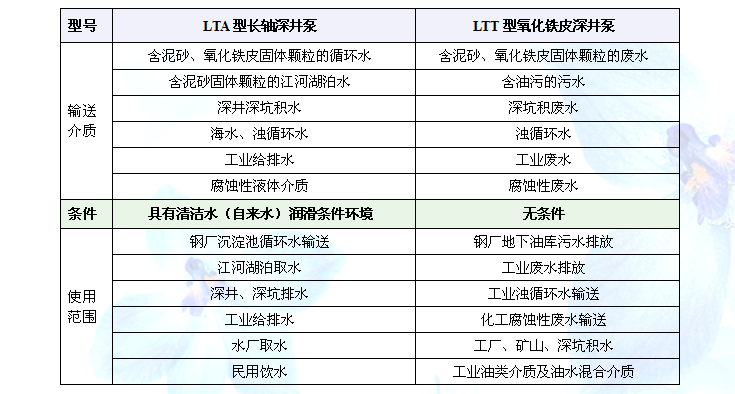

主要应用:

长轴深井泵运行注意事项:

1、每台班次必须检查泵体螺栓。

2、检查长轴深井泵填料是否有过大漏水现象,如有漏水及时添加盘根或全部更换。(长轴深井泵进行正常状态)

3、高速电机在运行中容易发热。当用手触摸电机端盖,如短时间感觉太烫,不能触摸,该机应停止运行。进行冷却,更换另一台机运行。

4、电机在运行中如发出“骨碌骨碌”声,表示轴承缺油,必须加油;如发出“梗梗”声,表示轴承内外钢圈或滚珠破损,应停机更换。更多内容:LC型立式长轴泵。

5、运行中突然停机或自动停机后,电机发生“嗡嗡”声,这是可能是电源缺相或主回路没有完全断开,应立即拉闸(总闸也可),否则会烧毁电机和设备。停机后必须查明原因,排除故障后再启动运行。

6、运行中水压表指针下跌,或水压表指针上不去。(不足8kg)这时可能进水管和水泵内有空气。如发现进水管中的橡皮短管有下陷现象,确定进水管滤网被堵塞,应立即停机消除滤网上杂务后再启动运行。

7、注意窨井污水,水位过高,必须启动排污泵排除。(及时停泵)

8、做好运行机械及仪表读数记录,并监视其变动,如电流表读数过高。必须停机查找原因,排除故障后再启动运行。

9、操作空气开关和检查配电柜时,应注意安全,避免触电。(*停电检查)

10、运行中的机械,切勿进行检修。如需维修,须先停机,并挂警示牌。

11、吃饭离岗前,启动运行的机械。必须注意观察水压、电压、电流及机械运行的状况。确实无异常时,方可离开。(在半小时以内)更多内容:TDLC型长轴泵。

12、水泵厂值班人员必须做到,上班不迟到,下班不早退,中途不离岗,有事先请假。

13、自动运行档位如果不能启动运行或运行数分钟后停机,则可能是自动讯号线路接触不良。必须停机检修(如修理后不到,改用手动按钮运行,同时要更换自动线路配件。)

14、水泵的联轴器的橡皮圈,必须每台班次检查一下,发现问题及更换。

15、水泵厂值班人员和维修人员的安全:必须做到手上没有水和潮气,才能操作电器开关。 为了确保水泵房的安全运行,按时供水,水泵厂值班人员上岗,必须安全操作。特制定本安全操作规程。

The long-axis deep well pump is mostly a vertical single-suction multi-stage centrifugal pump. The impeller is installed below the moving water level in the well. The power machine is placed on the well. The impeller is driven by the long shaft to rotate in the diversion shell. The water flows along the diversion shell and the impeller. The flow path between them is lifted up to the ground via the water pipe. The pump has a long service life and maintenance period, is widely used, and can be used in harsh environments, and is also extremely convenient for maintenance.

main feature:

●The transmission parts and lubrication parts are reliably protected by the protective tube

The protective tube structure is adopted to make the conveying medium flow outside the protective tube, and is not in contact with the transmission component and the lubricating component, and does not affect the transmission component and the lubricating component of the pump due to the foreign matter contained in the pump conveying medium containing mud sand, iron oxide scale and oil stain.

●Special lubrication method and bearing structure ensure long-term stable operation of the pump

In addition to the conventional rubber guide bearing, the pump bearing also uses graphite bearings and hard alloy bearings according to special needs to improve the wear resistance and temperature resistance of the pump.

The lubrication method of the pump can be used to lubricate the lower bearing of the pump with 2~3kg/cm2 tap water (clean water) depending on the environmental conditions. In the special environment without running water (clean water), the pump adopts self-lubricating method: one is lubricated with calcium-based grease, which is completely advanced technology. The pump can be used in any special environment. Normal long-term use. Another way of lubrication is to use the pump to transport the medium for self-lubrication when the pump is clean.

●Use high strength material, pump has good stability

The impeller and shaft of the pump are made of wear-resistant high-strength stainless steel. The pipe and the protective pipe are made of seamless steel pipe or stainless steel pipe with high strength and good stability.

●The pump can operate normally for a long time in a special harsh environment

●The pump is compact, easy to install, debug and maintain.

main application:

Long-axis deep well pump operation notes:

1. The pump body bolts must be checked for each shift.

2. Check whether the long shaft deep well pump packing has excessive water leakage. If there is water leakage, add packing or replace it all. (Long shaft deep well pump is in normal state)

3. High-speed motors are prone to heat during operation. When the motor end cover is touched by hand, if it feels too hot for a short time and cannot be touched, the machine should stop running. Cool down and replace another machine.

4. If the motor is in operation, it will sound “bone and bones”, indicating that the bearing is short of oil and must be refueled; if the sound of “stalk” is issued, it means that the inner and outer steel rings or balls are damaged, and should be replaced by stop. More: LC type vertical long axis pump.

5. After a sudden stop or automatic shutdown during operation, the motor will “beep”. This may be due to the lack of phase of the power supply or the main circuit is not completely disconnected. It should be pulled immediately (the main gate is also available), otherwise the motor will be burned and device. After the machine is stopped, the cause must be ascertained, and the operation should be started after the fault is eliminated.

6. The pointer of the water pressure gauge falls during operation, or the pointer of the water pressure gauge does not go. (less than 8kg) At this time, there may be air in the inlet pipe and the pump. If it is found that the rubber short pipe in the inlet pipe has a subsidence phenomenon, it is determined that the inlet pipe filter is blocked, and the machine should be stopped immediately to eliminate the chores on the filter network before starting the operation.

7, pay attention to the sewage well, the water level is too high, must start the sewage pump to eliminate. (stop pump in time)

8. Record the operating machinery and instrument readings and monitor their changes, such as the current meter reading is too high. You must stop the machine to find the cause, and then start the operation after troubleshooting.

9. When operating the air switch and checking the power distribution cabinet, pay attention to safety and avoid electric shock. (preferably power outage check)

10. Do not perform maintenance on the running machine. If maintenance is required, stop the machine first and hang the warning sign.

11. Start the running machinery before eating out of the post. Care must be taken to observe the conditions of water pressure, voltage, current and mechanical operation. If there is no abnormality, you can leave. (Within half an hour) More: TDLC long shaft pump.

12. The staff of the pump factory must do it. They are not late for work, do not leave early after work, do not leave the job in the middle, and have a leave in advance.

13. If the automatic running gear position cannot be started or stopped after a few minutes of running, the automatic signal line may be in poor contact. Must be shut down for maintenance (if not after repair, use the manual button to operate, and replace the automatic line accessories.)

14. The rubber band of the coupling of the pump must be checked every shift, and the problem is found and replaced.

15. Safety of the duty and maintenance personnel of the pump factory: It is necessary to operate the electrical switch without water and moisture on the hand. In order to ensure the safe operation of the pump house, water supply on time, the water pump factory on duty, must be safe to operate. This safety operation procedure is specially formulated.

Stainless steel hot spring pump

Long shaft deep well pump

Stainless steel deep well pump

Submersible electric pump

位于Schw?bischGmünd的凯森Kaysen泵业有限公司是世界*的各种流体水泵和隔膜泵制造商之一。60多年来,凯森以“制造”的可靠性和质量达到了*标准。凭借我们全面的产品组合,我们支持世界各地的客户成功掌握供水,采矿,工业,化工,造纸,电力,食品,制药,污水和海上行业的苛刻抽水任务。作为上述领域创新技术的*供应商,我们是液体需要安全,高效和经济运输的*合作伙伴。

位于Schw?bischGmünd的凯森Kaysen泵业有限公司是世界*的各种流体水泵和隔膜泵制造商之一。60多年来,凯森以“制造”的可靠性和质量达到了*标准。凭借我们全面的产品组合,我们支持世界各地的客户成功掌握供水,采矿,工业,化工,造纸,电力,食品,制药,污水和海上行业的苛刻抽水任务。作为上述领域创新技术的*供应商,我们是液体需要安全,高效和经济运输的*合作伙伴。

凯森始终坚持“重质量,讲信誉”为宗旨。产品现畅销全国各地,并已逐步开发海外市场。公司多次被评为“重合同讲信用”企业,深得用户的信赖和广泛的赞誉。

The Kaysen Pumps GmbH in Schw?bischGmünd, Germany, is one of the world's leading manufacturers of fluid centrifugal pumps and diaphragm pumps. For more than 60 years, Kaisen has achieved the highest standards of reliability and quality of "Made in Germany". With our comprehensive product portfolio, we support customers around the world to successfully grasp the harsh pumping tasks of water supply, mining, industry, chemical, paper, electricity, food, pharmaceutical, sewage and marine industries. As a leading provider of innovative technology in these areas, we are the perfect partner for liquids to be safe, efficient and economical to transport. ,

Germany Kaysen always adhere to the "quality, stresses credibility" for the purpose. Products are selling all over the country, and has gradually developed overseas markets. The company has repeatedly been rated as "the contract with the letter" business, won the trust of users and extensive praise.