|

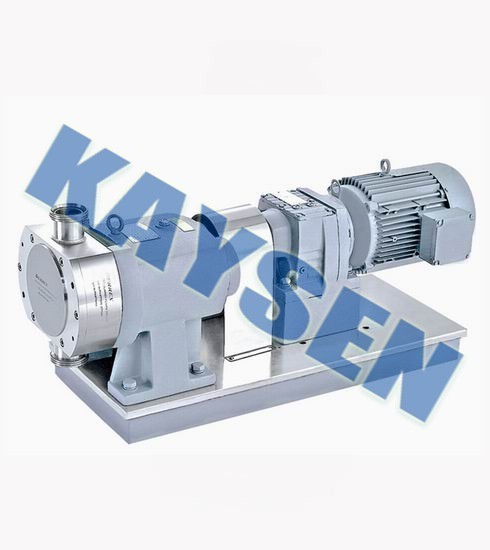

- 品牌:德国KAYSEN

- 货号:KS8369679

- 发布日期: 2019-10-12

- 更新日期: 2026-01-22

| 外型尺寸 | |

| 货号 | KS8369679 |

| 品牌 | KAYSEN |

| 用途 | 抽水、化工、制药、石油、冶金、染料、冶炼、电力、电镀、农药、造纸、食品、纺织等行业酸洗工艺、制酸制碱、喷漆工艺、有色金属冶炼中的电解液输送、离子膜项目中的氯水输送、废水处理、电镀、农药领域。 |

| 型号 | KAYSEN |

| 工作压差 | 0 |

| 压力环境 | 常压 |

| 介质温度 | 250℃ |

| 驱动方式 | 电动 |

| 适用介质 | 水 |

浓浆泵-转子泵-KAYSEN泵业

GERMANY KAYSEN PUMP CO .,LTD

浓浆泵是一种单螺杆式输送泵,它的主要工作部件是偏心螺旋体的螺杆(称转子)和内表面呈双线螺旋面的螺杆衬套(称定子)。浓浆泵中凡接触物料的金属零件均选用优质不锈钢制作,衬筒采用无毒无味的信用橡胶,工作温度可达100℃可用于输送食品浆料和粘度1-1000000厘泊含有固体颗粒或胶圬的溶液浆,悬浮液的腐蚀介质。

主要特点:

●可输送高浓度高粘度1-1000000厘泊溶液浆

●自吸能力强,不用装底阀可直接抽吸液体。

●运转平稳、振动、噪声小。

●结构简单、拆装维修方便。

主要应用:浓浆泵故障排除

适应高粘度介质的特殊输送,尤其在化工厂、酿造厂、食品厂、造纸厂、罐头厂、药厂、酒厂等单位使用广泛,基于此,浓浆泵得到全国各工矿企业、各科研单位普遍征用,效果良好。

浓浆泵故障排除:

螺杆浓浆泵启动困难:螺杆浓浆泵料液未充满泵腔,摩擦阻力较大。

螺杆浓浆泵填料压盖压得过紧,轴与填料之间有摩擦力矩过大:用管子钳搬动联轴器泵主轴3~6转,调整填料压盖。

螺杆浓浆泵启动后不出料液:螺杆浓浆泵有大量空气吸入;

螺杆浓浆泵电动机转向不对;

螺杆浓浆泵料液粘度过大:检查吸入口液位是否太低,吸入管是否漏气;调接电动机的任意两相进线;稀释料液。

螺杆浓浆泵有圈套的振动或噪音,螺杆浓浆泵电动机与泵轴不同心;

螺杆浓浆泵浆泵泵内吸入空气或料液混有大量空气。重新调整同轴度;检查料液位,设法排除吸入液中的空气。

螺杆浓浆泵运行过程中,流量显著下降,螺杆浓浆泵衬套磨损,间隙增大。

螺杆浓浆泵转速降低。

螺杆浓浆泵万向联轴节或绕轴损坏传动失效;

螺杆浓浆泵遇到故障问题了有什么解决办法?

螺杆浓浆泵吸入管路浸入液体深度不够,有空气进入泵内,更换衬套,必要时换螺杆;检查电源和电机;停机检修,更换轴联轴节或绕轴;减小吸入高度,增加浸入深度,拔除吸入料液中空气。

螺杆浓浆泵电动机超载,浓浆泵扬程超过泵的扬程式过多;

螺杆浓浆泵料液粘度太大。

螺杆浓浆泵电压太低,尽量减小管路水头损失,或更换高扬程泵。稀释料液;检查原因,提高电压至规定值。

螺杆浓浆泵轴封填料处大量漏液,浓浆泵压盖过松;螺杆浓浆泵填料磨损;

螺杆浓浆泵进出口位置相反,调整压盖;更换填料;以中间法兰口为吸入口。

选型时必需的主要运行数据有:

螺杆浓浆泵输送介质名称、腐蚀性、磨蚀性、粘度、固体含量、工作温度;

运行参数流量或流量范围、*压力、连续或间断运行;

安装环境卧式或立式、固定或移动、连接管路的特殊要求、防爆防护要求。

Rotor pump

Emulsifying pump

Positive displacement pump

The thick slurry pump is a single-screw transfer pump. Its main working components are the screw of the eccentric spiral (called the rotor) and the screw bushing (called the stator) with the double-sided spiral surface on the inner surface. The metal parts of the thick slurry pump are made of high quality stainless steel. The liner is made of non-toxic and tasteless credit rubber. The working temperature can reach 100°C. It can be used to transport food slurry and viscosity 1-1000000 centipoise containing solid particles or glue. A solution of cerium, a corrosive medium for the suspension.

main feature:

●It can transport high concentration and high viscosity 1-1000000 centipoise solution slurry

●The self-priming ability is strong, and the liquid can be directly sucked without the bottom valve.

● Smooth operation, vibration and low noise.

●Simple structure, convenient disassembly and assembly.

Main application: Troubleshooting of thick slurry pump

It is suitable for special transportation of high-viscosity medium, especially in chemical plants, breweries, food factories, paper mills, canneries, pharmaceutical factories, wineries, etc. Based on this, the thick slurry pump has obtained various industrial and mining enterprises and scientific research units in the country. Universal requisition, the effect is good.

Thickener pump troubleshooting:

Difficulty in starting the screw slurry pump: the screw slurry pump fluid does not fill the pump chamber and the frictional resistance is large.

The screw grouting pressure of the screw thick pump is too tight, and the friction torque between the shaft and the packing is too large: use the pipe wrench to move the main shaft of the coupling pump 3 to 6 turns, and adjust the packing gland.

After the screw slurry pump is started, no liquid is discharged: the screw slurry pump has a large amount of air inhalation;

The screw slurry pump motor is not turning right;

The viscosity of the screw slurry pump liquid is too large: check if the liquid level of the suction port is too low, and whether the suction pipe leaks; adjust any two-phase incoming line of the motor; dilute the liquid.

The screw thick slurry pump has a trap of vibration or noise, and the screw thick pump motor is not concentric with the pump shaft;

The inhaled air or the liquid in the pump of the screw slurry pump is mixed with a large amount of air. Re-adjust the concentricity; check the level of the material and try to remove the air from the inhalation.

During the operation of the screw slurry pump, the flow rate drops significantly, and the screw slurry pump bushing wears and the gap increases.

The screw slurry pump speed is reduced.

The screw joint pump or the shaft is damaged by the screw thick pump;

What is the solution to the problem of the screw slurry pump encountering the fault?

The screw slurry pump suction line is not deeply immersed in the liquid, there is air entering the pump, the bushing is replaced, and the screw is changed if necessary; check the power supply and the motor; stop the repair, replace the shaft coupling or the shaft; reduce the suction height, increase At the immersion depth, remove the air from the suction liquid.

The screw thick pump motor is overloaded, and the lift pump head exceeds the pump's excessive lift;

The viscosity of the screw slurry pump liquid is too large.

The screw slurry pump voltage is too low, try to reduce the pipe head loss, or replace the high lift pump. Dilute the liquid; check the cause and increase the voltage to the specified value.

A large amount of liquid is leaked from the shaft seal packing of the screw thick slurry pump, and the thick slurry pump cover is too loose; the screw thick slurry pump packing wears;

The inlet and outlet of the screw slurry pump are opposite in position, and the gland is adjusted; the packing is replaced; the intermediate flange port is used as the suction port.

The main operational data required for the selection is:

The screw slurry pump conveys the name of the medium, corrosivity, abrasion, viscosity, solid content, working temperature;

Operating parameter flow or flow range, maximum pressure, continuous or intermittent operation;

Installation environment Horizontal or vertical, fixed or moving, connecting pipeline special requirements, explosion protection requirements.

位于Schw?bischGmünd的凯森Kaysen泵业有限公司是世界*的各种流体水泵和隔膜泵制造商之一。60多年来,凯森以“制造”的可靠性和质量达到了*标准。凭借我们全面的产品组合,我们支持世界各地的客户成功掌握供水,采矿,工业,化工,造纸,电力,食品,制药,污水和海上行业的苛刻抽水任务。作为上述领域创新技术的*供应商,我们是液体需要安全,高效和经济运输的*合作伙伴。

位于Schw?bischGmünd的凯森Kaysen泵业有限公司是世界*的各种流体水泵和隔膜泵制造商之一。60多年来,凯森以“制造”的可靠性和质量达到了*标准。凭借我们全面的产品组合,我们支持世界各地的客户成功掌握供水,采矿,工业,化工,造纸,电力,食品,制药,污水和海上行业的苛刻抽水任务。作为上述领域创新技术的*供应商,我们是液体需要安全,高效和经济运输的*合作伙伴。

凯森始终坚持“重质量,讲信誉”为宗旨。产品现畅销全国各地,并已逐步开发海外市场。公司多次被评为“重合同讲信用”企业,深得用户的信赖和广泛的赞誉。

The Kaysen Pumps GmbH in Schw?bischGmünd, Germany, is one of the world's leading manufacturers of fluid centrifugal pumps and diaphragm pumps. For more than 60 years, Kaisen has achieved the highest standards of reliability and quality of "Made in Germany". With our comprehensive product portfolio, we support customers around the world to successfully grasp the harsh pumping tasks of water supply, mining, industry, chemical, paper, electricity, food, pharmaceutical, sewage and marine industries. As a leading provider of innovative technology in these areas, we are the perfect partner for liquids to be safe, efficient and economical to transport. ,

Germany Kaysen always adhere to the "quality, stresses credibility" for the purpose. Products are selling all over the country, and has gradually developed overseas markets. The company has repeatedly been rated as "the contract with the letter" business, won the trust of users and extensive praise.