|

- 品牌:德国KAYSEN

- 发布日期: 2020-09-11

- 更新日期: 2026-01-22

| 外型尺寸 | |

| 品牌 | 德国KAYSEN |

| 货号 | |

| 用途 | 水 |

| 型号 | KAYSEN |

| 工作压差 | 0 |

| 压力环境 | 常压 |

| 介质温度 | 250℃ |

| 驱动方式 | 电动 |

| 适用介质 | 水 |

渣浆泵

渣浆泵-原装品质销售

凯森泵业有限公司,是集研发、销售、服务于一体的隔膜泵专业厂商。主打产品气动隔膜泵系列、电动隔膜泵系列,性价比高,质量稳定,被广泛的运用在化工、环保、油田、制药、食品、冶金、造纸、电力、印染等领域。

Germany Kaysen Pump Industry Co., Ltd. is a professional manufacturer of diaphragm pumps integrating R&D, sales and service. The main products are pneumatic diaphragm pump series and electric diaphragm pump series, which are cost-effective and stable in quality. They are widely used in the fields of chemical industry, environmental protection, oil field, pharmaceuticals, food, metallurgy, papermaking, electricity, printing and dyeing.

渣浆泵核心优势core advantages

首先讲述一下离心泵和渣浆泵的关系,然后渣浆泵原理也就自然清晰了。离心概念是从泵原理来讲的。泵有许多种,依据不同的角度可划分几十个类别。离心泵是从泵的工作原理上划分,是通过离心力作用来达到给输送介质增压的过程。另外还有常见的种类包括螺杆原理,柱塞原理等可以划分出不同于离心原理的泵。说完离心泵概念,再说渣浆泵,渣浆泵又是从另外一个角度来划分泵的,即从输送介质来划分的。顾名思义,渣浆泵输送的是含有渣滓的固体颗粒与水的混合物。但从原理上讲渣浆泵属于离心泵的一种。离心泵的主要工作部件是叶轮和机壳,机壳内的叶轮装置位于轴上,并与原动机连接形成一个整体。当原动机机带动叶轮旋转时,叶轮中的叶片迫使流体旋转,即叶片对流体沿它的运动方向做功,从而迫使流体的压力势能和动能增加。与此同时,流体在惯性力的作用下,从中心向叶轮边缘流去,并以很高的的速度流出叶轮,进入压出室,再经扩散管排出,这个过程称为压水过程。同时,由于叶轮中心的流体流向边缘,在叶轮中心形成低压区,当它具有足够的真空时,在吸入端压强的作用下(一般是大气压强),流体经吸入室进入叶轮,这个过程称为吸水过程。由于叶轮连续的旋转,流体也就连续的排出、吸入,形成连续的工作。离心式的泵(包括渣浆泵)的工作过程,实际上是一个能量传递和转化的过程。它将电动机高速旋转的机械能,通过泵的叶片传递并转化为被抽升流体的压能和动能。

First, tell us about the relationship between the centrifugal pump and the slurry pump, and then the principle of the slurry pump is naturally clear. The centrifugal concept is based on the pump principle. There are many types of pumps, which can be divided into dozens of categories according to different angles. The centrifugal pump is divided from the working principle of the pump, which is the process of pressurizing the conveying medium through the action of centrifugal force. In addition, there are common types including screw principle, plunger principle, etc. which can be divided into pumps that are different from the centrifugal principle. After talking about the centrifugal pump concept, let's talk about the slurry pump. The slurry pump divides the pump from another angle, that is, it is divided from the conveying medium. As the name suggests, the slurry pump transports a mixture of solid particles containing scum and water. But in principle, the slurry pump is a kind of centrifugal pump. The main working parts of the centrifugal pump are the impeller and the casing. The impeller device in the casing is located on the shaft and connected with the prime mover to form a whole. When the prime mover drives the impeller to rotate, the blades in the impeller force the fluid to rotate, that is, the blades do work on the fluid along its moving direction, thereby forcing the pressure potential and kinetic energy of the fluid to increase. At the same time, the fluid flows from the center to the edge of the impeller under the action of inertial force, and flows out of the impeller at a high speed, enters the extruding chamber, and then is discharged through the diffuser. This process is called the pressurized water process. At the same time, because the fluid in the center of the impeller flows to the edge, a low pressure zone is formed in the center of the impeller. When it has sufficient vacuum, under the action of the suction end pressure (generally atmospheric pressure), the fluid enters the impeller through the suction chamber. This process is called Water absorption process. Due to the continuous rotation of the impeller, the fluid is continuously discharged and sucked in to form continuous work. The working process of centrifugal pumps (including slurry pumps) is actually a process of energy transfer and conversion. It transfers the mechanical energy of the motor at high speed through the pump blades and converts it into the pressure energy and kinetic energy of the pumped fluid.

渣浆泵材质Material

为何Kaysen渣浆泵如此通用?

它们采用多种泵材料制造,包括高铬耐磨合金、氟塑料

Why is Kaysen slurry pump so versatile?

They are made of a variety of pump materials, including high chromium wear-resistant alloys, fluoroplastics

渣浆泵应用application

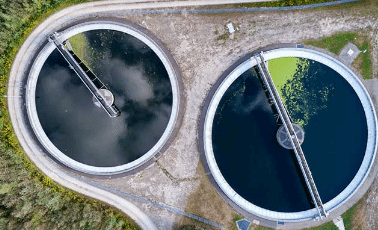

水/废水→Water/waste water

您的废水处理服务和设备的*来源

我们有水和废水团队,以了解*提高设施中设备的可靠性。

The source of your wastewater treatment services and equipment

We have a water and wastewater team to understand and improve the reliability of equipment in the facility.

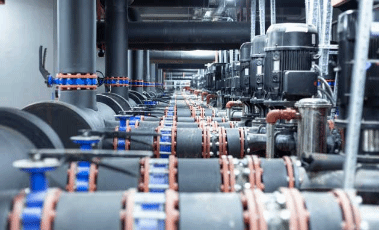

一般工业→General industry

您可以信赖的专家所需的设备

提供流体技术和专业知识,以降低您的运营成本,提高效率并帮助实现您的性能目标。

60多年来,我们一直在帮助一般工业领域的人员解决他们在流体工艺方面最棘手的挑战。通读我们的一些成功案例,了解我们*帮助像您这样的企业提高效率并降低运营成本。

The equipment you need from an expert you can trust

Provide fluid technology and expertise to reduce your operating costs, increase efficiency and help achieve your performance goals.

For more than 60 years, we have been helping people in the general industry to solve their most difficult challenges in fluid technology. Read through some of our success stories and learn about us* helping companies like you increase efficiency and reduce operating costs.

制浆造纸→Pulp and Paper

为制浆造纸业服务60多年

丰富的经验以帮助降低运营成本并提高工厂效率。与纸浆和造纸工艺经验丰富的工程师交谈,并从今天开始。

Serving the pulp and paper industry for more than 60 years

Rich experience to help reduce operating costs and increase plant efficiency. Talk to experienced engineers in the pulp and paper process and start today.

饮料→Drink

每个饮料领域都面临着独特的挑战。卫生,过程效率,废水处理和设备可靠性只是当今饮料制造商面临的一些挑战。

精通流体技术专业知识,可帮助您降低运营成本并提高设施效率。立即与工程师交谈。

Each beverage sector faces unique challenges. Hygiene, process efficiency, wastewater treatment and equipment reliability are just some of the challenges faced by beverage manufacturers today.

Proficient in fluid technology expertise can help you reduce operating costs and improve facility efficiency. Talk to the engineer immediately.

化工/石化→Chemical/Petrochemical

流体处理系统超出性能要求

稀,稠,易挥发或有害化学物质?我们可以帮助您找到满足生产和性能需求的*方法。我们将帮助确保您安装的流体系统解决方案将通过提高生产效率,延长设备使用寿命和降低能耗来降低运营成本。

Fluid handling system exceeds performance requirements

Thin, thick, volatile or harmful chemicals? We can help you find the best way to meet your production and performance needs. We will help ensure that the fluid system solution you install will reduce operating costs by increasing production efficiency, extending equipment life and reducing energy consumption.

生物燃料→Biofuels

坚固耐用的设备可满足您的需求

生物燃料生产需要流体技术,该技术可以满足苛刻的服务要求并全天候运行。Kaysen为生物燃料生产商汇集了一些*的流体技术品牌,以提高可靠性并降低总拥有成本。

Rugged equipment to meet your needs

Biofuel production requires fluid technology, which can meet demanding service requirements and operate around the clock. Kaysen brings together some of the best fluid technology brands for biofuel producers to improve reliability and reduce total cost of ownership.

乳制品→Dairy products

您需要安全处理乳制品的技术

清洁和卫生是乳制品加工的基石。Kaysen不仅为您的乳品厂提供乳品加工设备和系统,我们还提供耐腐蚀的地板涂料,使地板更易于清洁,同时保护混凝土不受侵蚀。

You need technology to safely handle dairy products

Cleanliness and hygiene are the cornerstones of dairy processing. Kaysen not only provides dairy processing equipment and systems for your dairy factory, we also provide corrosion-resistant floor coatings that make the floor easier to clean and protect the concrete from corrosion.

食物→food

从食品生产和包装,到废水处理,我们可以满足您的卫生级要求,而且还可以实现您的绩效目标。

只需一个电话即可节省能源,提高可靠性并提高效率。与我们交谈并开始。

From food production and packaging to wastewater treatment, we can meet your sanitary requirements and also achieve your performance goals.

Just a phone call can save energy, increase reliability and increase efficiency. Talk to us and start.

发电→Power generation

达到并超越您的绩效目标的设备和专业知识

对电力的需求永无止境。我们也没有。我们提供高度可靠的泵,阀门,过滤器,机械密封件和控件,这些控件对于加热或加工产生的电能和蒸汽至关重要。

依靠Kaysen可以提高生产效率,延长设备生命周期并降低能耗,从而帮助降低运营成本。

Equipment and expertise to meet and exceed your performance goals

The demand for electricity is endless. Neither do we. We provide highly reliable pumps, valves, filters, mechanical seals and controls that are essential for heating or processing electricity and steam.

Relying on Kaysen can improve production efficiency, extend equipment life cycle and reduce energy consumption, thereby helping to reduce operating costs.

制药→Pharmaceutical

对于药品,它需要清洁得多

我们了解它不仅需要清洁。药品生产需要高水平的照护,记录和精确度。起重机工程部提供全面的泵,密封件,阀门,CIP系统等产品线,以帮助您超越性能目标。

For medicines, it needs to be much cleaner

We understand that it needs more than just cleaning. Pharmaceutical production requires a high level of care, records and precision. The Crane Engineering Department provides a comprehensive product line of pumps, seals, valves, CIP systems, etc. to help you exceed performance goals.